Construction

Injection Moulding for Construction Applications

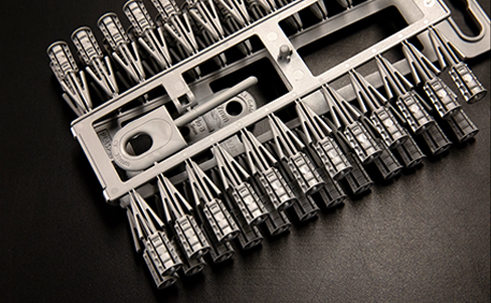

Stephens Plastic Mouldings is a leading provider of construction injection moulding solutions, offering precision, cost-efficiency, and durability for the construction industry. With extensive expertise in producing bespoke plastic components, we cater to a wide range of needs, from tools and machinery parts to architectural components.

Why Use Injection Moulding in Construction?

Injection moulding is integral to construction, offering unmatched scalability and efficiency for manufacturing plastic components.

It delivers:

- High Durability: Essential for components subjected to heavy use and environmental stress.

- Cost Efficiency: Minimises waste while providing low-cost, high-volume production.

- Custom Design Flexibility: Allows tailored solutions for diverse construction applications.

- Material Versatility: Options for lightweight, robust, and weather-resistant plastics ensure long-lasting components.

Capabilities of Stephens Plastic Mouldings in Construction Injection Moulding

Our construction injection moulding services include:

Parts for tools, machines, and structural applications tailored to meet specific project requirements.

Our advanced moulding techniques ensure accuracy across small to large production runs.

From polypropylene and polycarbonate to nylon, we select materials for maximum durability and performance.

Test designs efficiently before scaling up production, ensuring minimal delays in your projects.

Applications of Injection Moulding in Construction

Stephens Plastic Mouldings supports various construction applications, such as:

- Pipes and Guttering: Lightweight, durable solutions for plumbing and drainage.

- Roofing and Flooring Components: Precision-crafted parts for architectural integrity.

- Insulation and Cladding Panels: Enhancing energy efficiency in buildings.

- Cabling, Casing, and Connectors: Safe and robust solutions for electrical systems.

- Personal Protective Equipment: Helmets and other PPE tailored for safety compliance.

Why Choose Stephens Plastic Mouldings for Construction Injection Moulding?

- ISO 9001 Certified: Guarantees the highest quality and safety standards.

- Industry Experience: Decades of expertise serving the construction sector.

- Customer-Centric Approach: Tailored solutions to meet your specific project goals.

- Advanced Technology: State-of-the-art processes ensure precision and efficiency in every production run.

FAQs

We produce parts like pipes, connectors, cladding panels, roofing materials, and machine components.

Common materials include polypropylene, polyethylene, polycarbonate, and nylon for durability and flexibility.

It offers customisation, cost savings, and scalability for high-quality components designed to meet strict industry standards.

Prototyping can take days, while full-scale production typically takes 2-6 weeks, depending on complexity.

Yes, we are equipped for high-volume production while maintaining quality and precision.

Get Started Today

Partner with Stephens Plastic Mouldings for your next construction project.

Contact us

For a consultation and see how our construction injection moulding services can streamline your manufacturing needs.

Call 0121 544 5808 OR Email sales@stephensplasticmouldings.co.uk.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.