The Impact of Injection Moulding On The Environment & Sustainability

10 April 2025

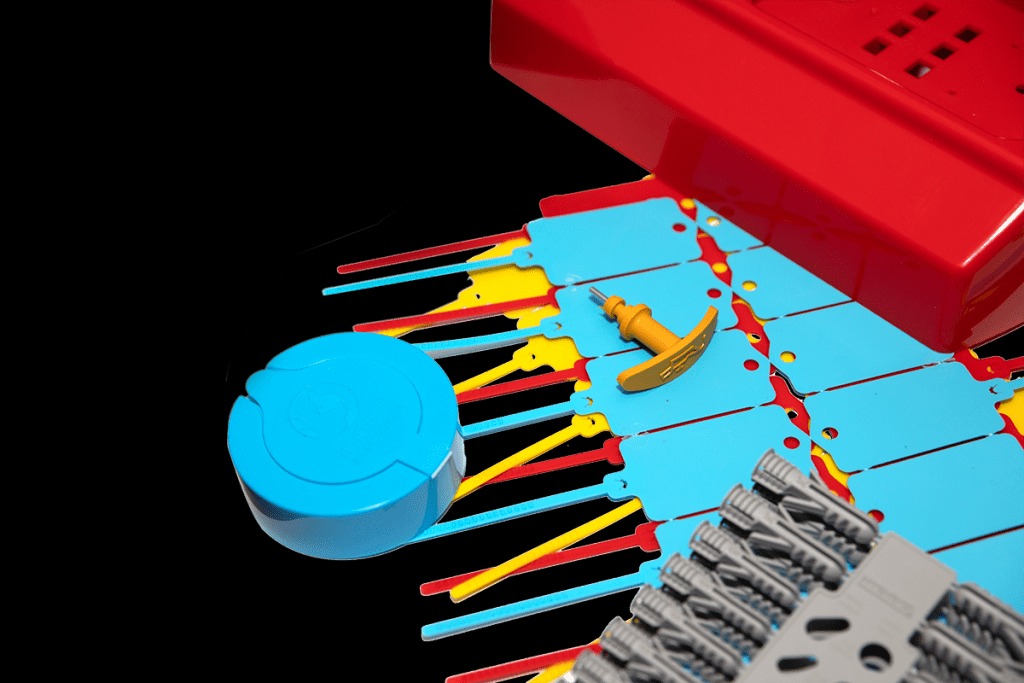

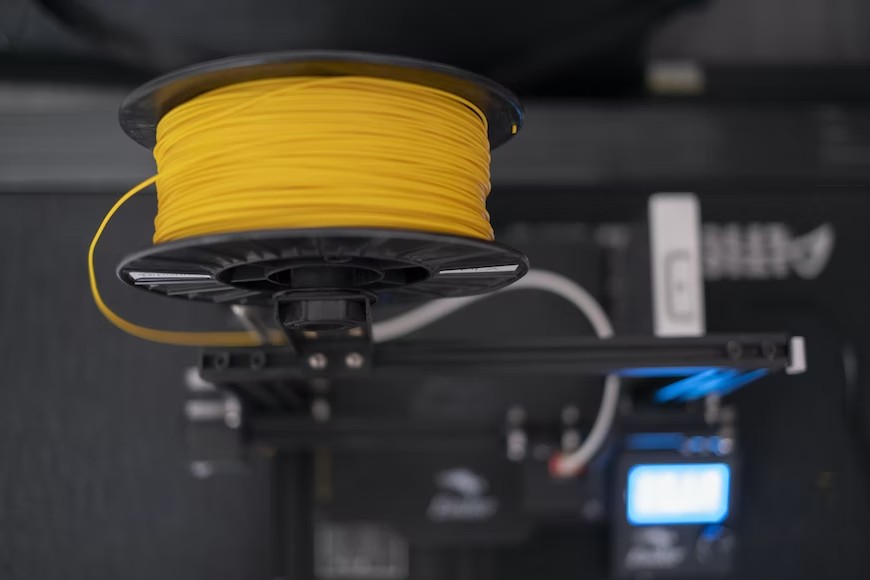

Injection moulding is a popular manufacturing process. It involves the creation of plastic parts by melting them down and injecting them into a mould. But, is injection moulding good for the environment? The injection moulding environmental impact has been a topic of discussion among manufacturers and environmentalists over the years. So, today we will discuss […]