Understanding Minimum Order Quantities in Plastic Injection Moulding

22 November 2024

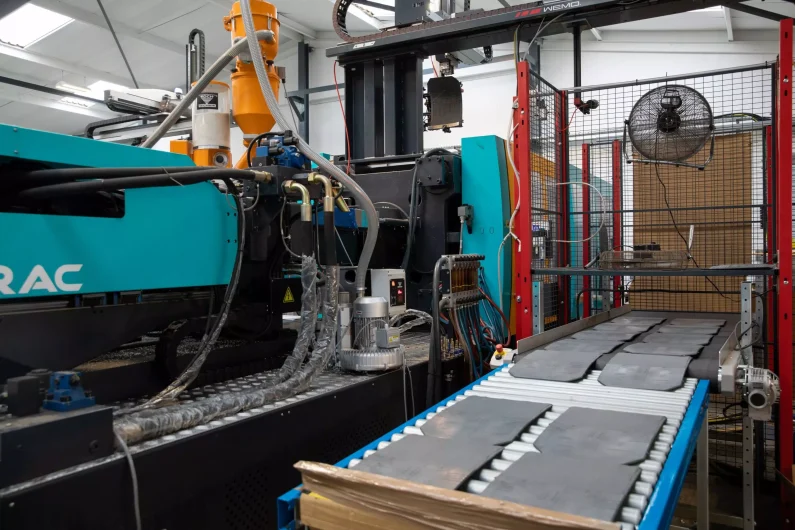

Understanding Minimum Order Quantities in Plastic Injection Moulding: A Stephens Plastic Mouldings Guide In the manufacturing world, efficiency and cost-effectiveness often depend on Minimum Order Quantities (MOQ). At Stephens Plastic Mouldings, we understand that every project is unique, which is why we strive to balance economic viability with your specific needs. Let’s explore how MOQs […]