Why ABS Plastic Is a Game – Changer in Automotive Injection Moulding

25 November 2025

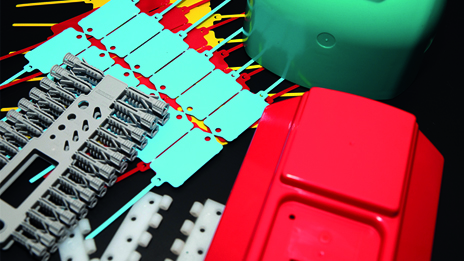

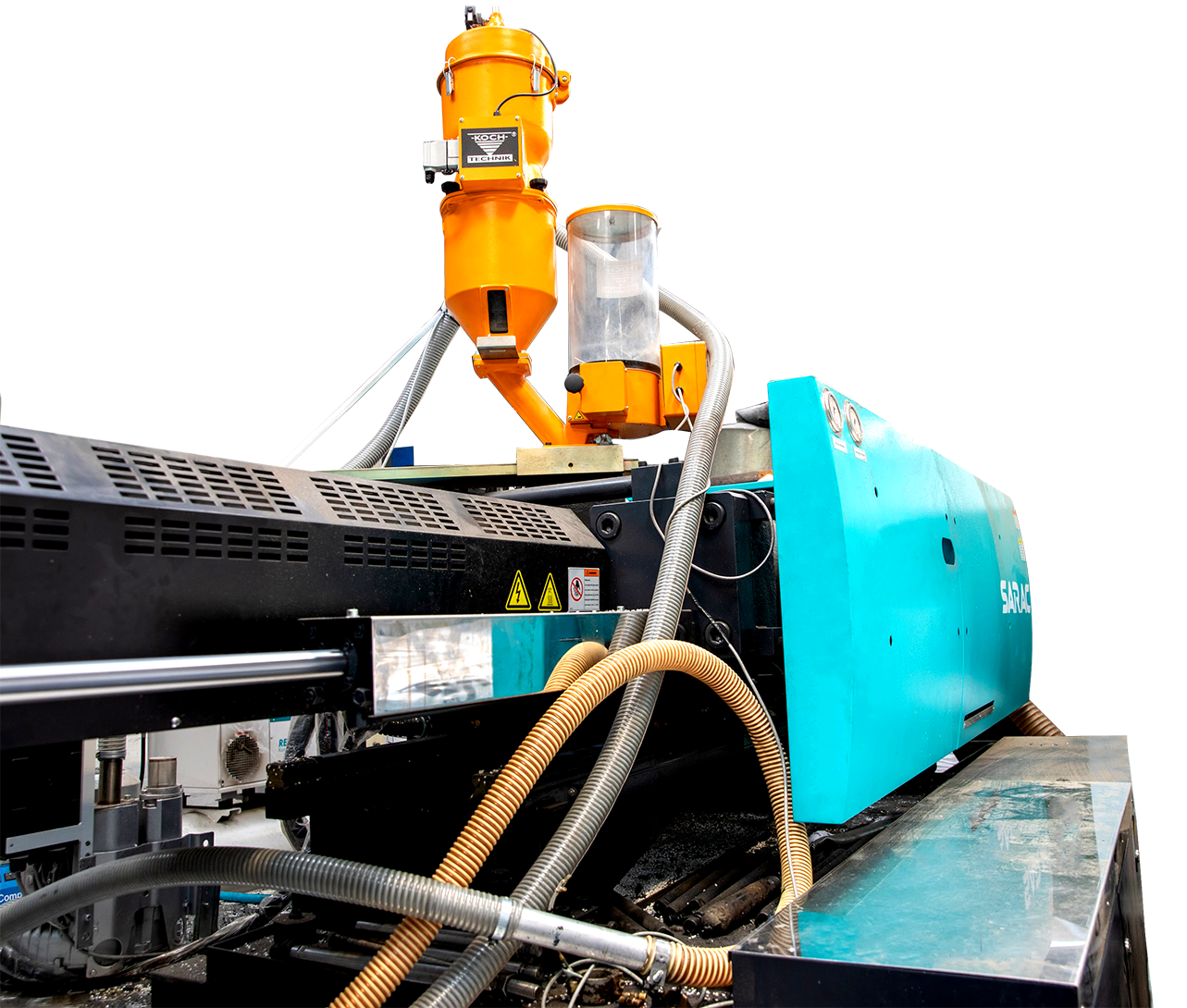

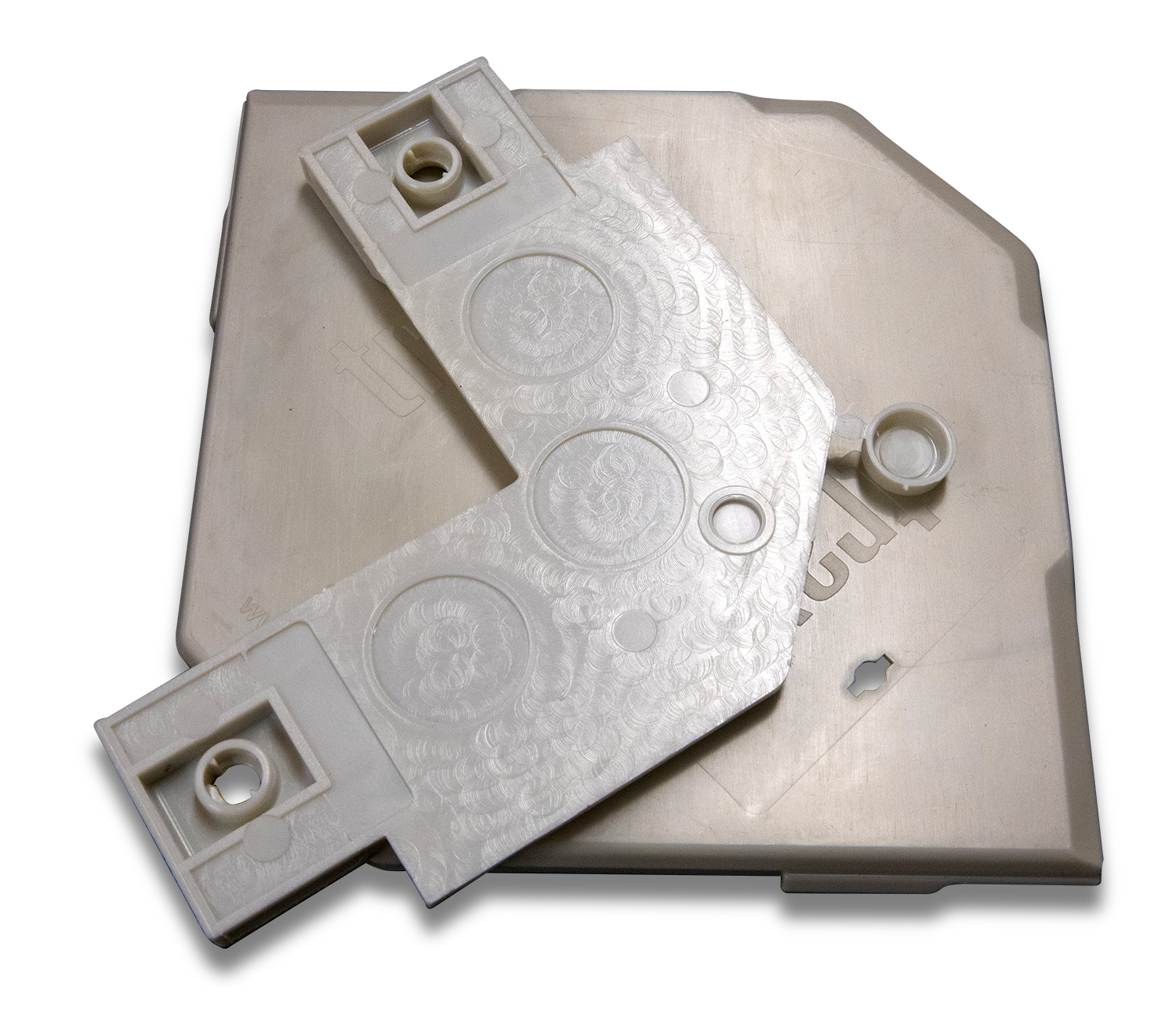

Material Innovation That Drives Performance, Reliability & Cost Efficiency As a trusted UK-based manufacturer, Stephens Plastic Mouldings supports the automotive sector with precision-moulded plastic components designed for durability, design flexibility, and high performance. One of the standout materials we use for this purpose is ABS (Acrylonitrile Butadiene Styrene) – a thermoplastic that has transformed how […]