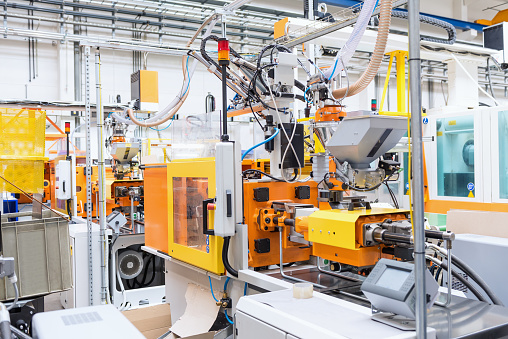

Why Choose Stephen’s Plastics For Plastic Injection Moulding In Electronics

18 April 2025

The advancement of technology has made many sectors use electronic goods to enhance operational efficiency. Consequently, we must optimise design and usability. Using plastic injection moulding, you can reduce costs turnovers of electric goods and increase product quality and production rates. Here at Stephens Plastic Mouldings, our plastic injection moulding services in London are renown […]