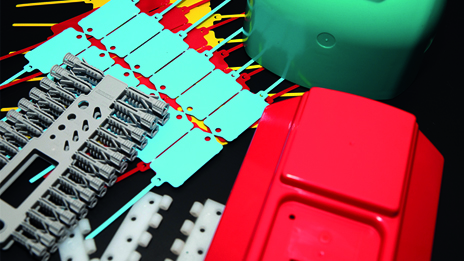

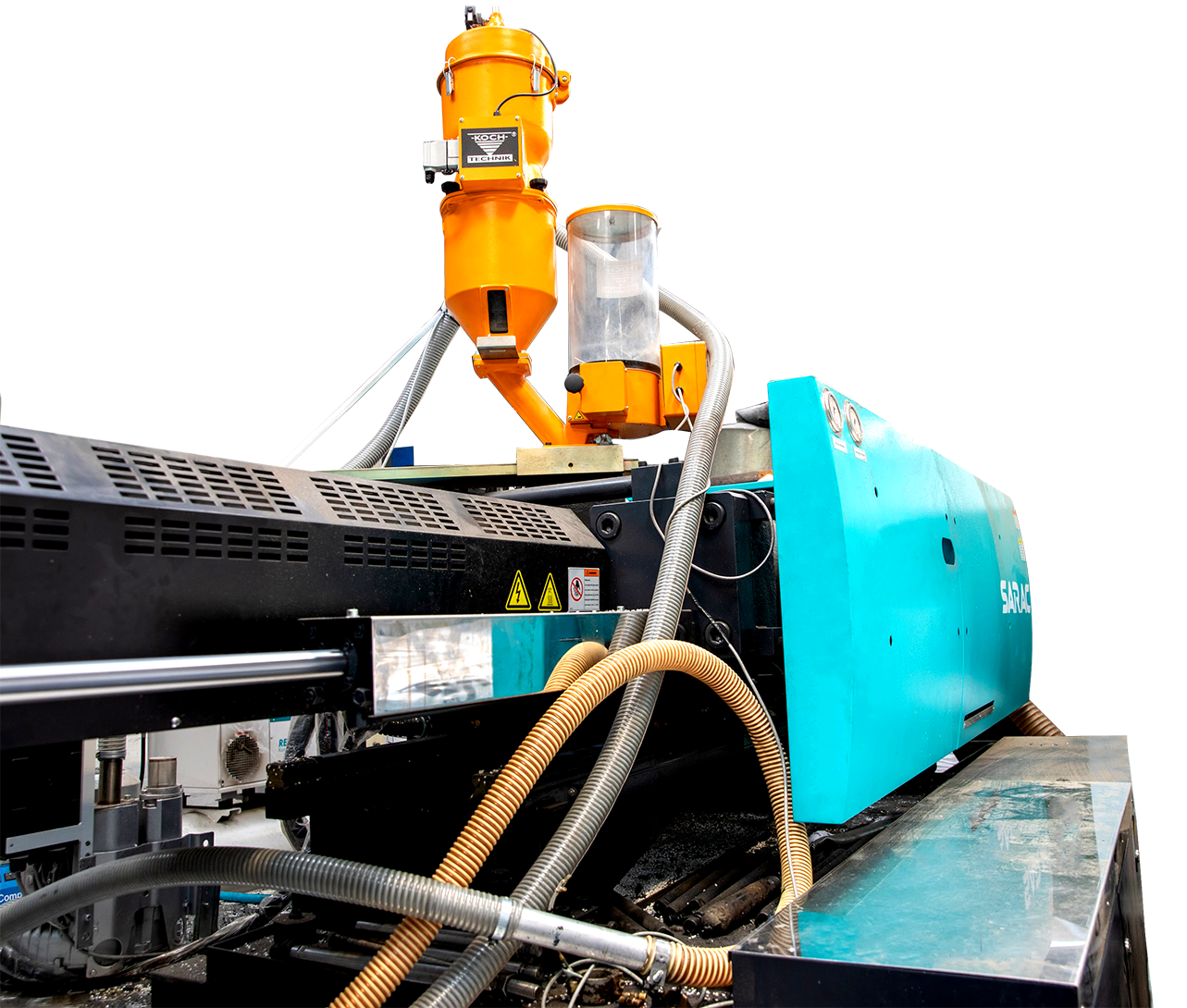

Sustainable Manufacturing in Plastic Injection Moulding: How Eco-Friendly Practices Drive Profitability

8 December 2025

Sustainability Is No Longer Optional in Manufacturing Sustainability in manufacturing has moved beyond environmental responsibility. In modern plastic injection moulding, it is now a commercial necessity. At Stephens Plastic Mouldings, sustainable manufacturing is not a marketing concept. It is a practical, engineering-led approach to reducing waste, improving efficiency, stabilising costs and protecting long-term return on […]