How Is Plastic Injection Moulding Helping Automotive Manufacturers in Birmingham Drive Efficiency?

2 August 2025

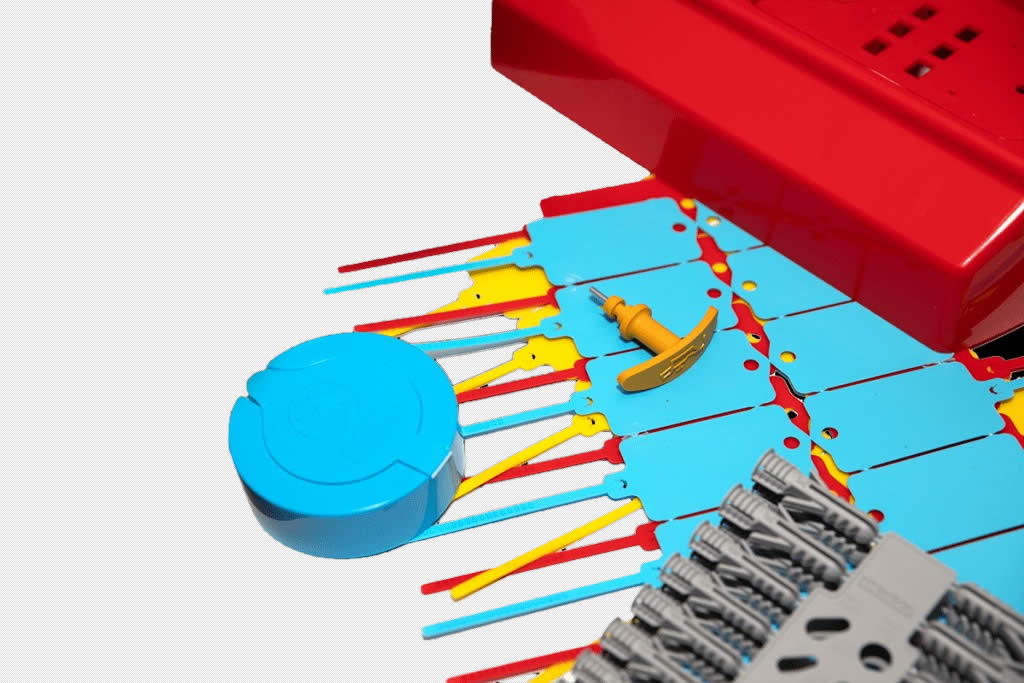

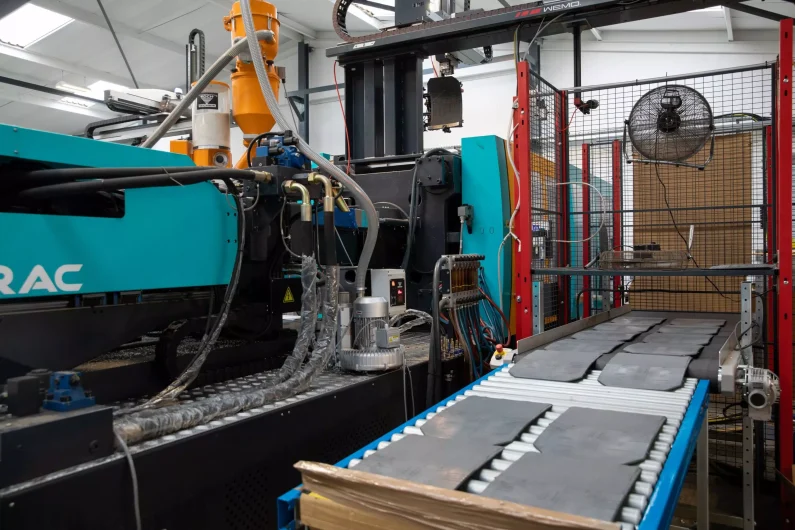

Accelerating Innovation for Birmingham’s Automotive Sector Birmingham remains a powerhouse in the UK’s automotive industry, with a proud legacy of innovation and advanced engineering. As vehicle platforms become lighter, smarter, and more modular, manufacturers are increasingly turning to plastic injection moulding to reduce weight, increase part precision, and optimise cost. Stephens Plastic Mouldings supports automotive […]