Step-by-Step Guide to the Plastic Injection Moulding Process

20 June 2024

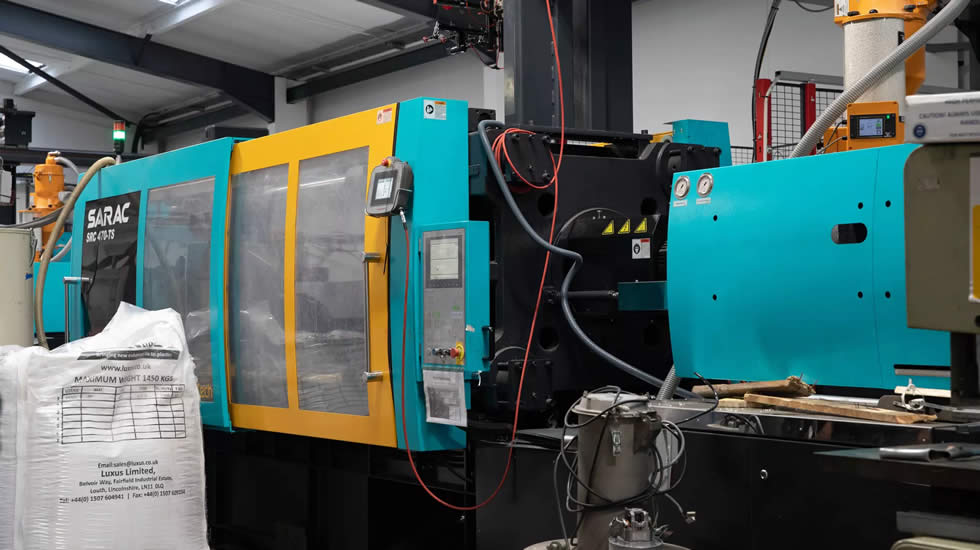

Summary. Plastic injection moulding is a cornerstone of modern manufacturing, essential for creating products across various industries. At Stephens Plastic Mouldings, we excel in this field by educating clients on injection moulding techniques and the plastic injection moulding process. Our guide covers design, mould creation, material selection, moulding, cooling, post-processing, and quality control, ensuring high-quality […]