Plastic Injection Moulding Companies

Plastic Injection Moulding Companies

You will see why Stephens Plastic Mouldings deliver results as you use our services for the research and design or manufacturing, or for your entire project implementation of plastic injection mouldings. Based on our wealth of experience gained in the course of more than two decades, we have established a rigorous structure and expertise in plastic injection mouldings manufacturing; the entire range of precision plastic components for industrial uses as well as consumer staples for everyday use is an area where we excel. We are equally expert and painstaking implementers in the design and prototype stage, and in the manufacturing of plastic injection moulding, and we are dedicated to the introduction of innovations that enhance the quality and efficiency of mouldings made for any purposes. All areas of mouldings design and manufacturing are matters we are experienced and proficient in. The research and design, the prototype preparation, the tooling, the project management as a whole, all stages of plastic injection mouldings are fields in which our team invariably delivers quality and timeliness.

Looking for companies to provide a plastic injection moulding service?

Have an idea or ready to get your product moulded?

We can provide a quote or more information for all injection moulding so look no further for plastic injection moulding companies – contact us today!

The materials and process used by plastic injection moulding companies:

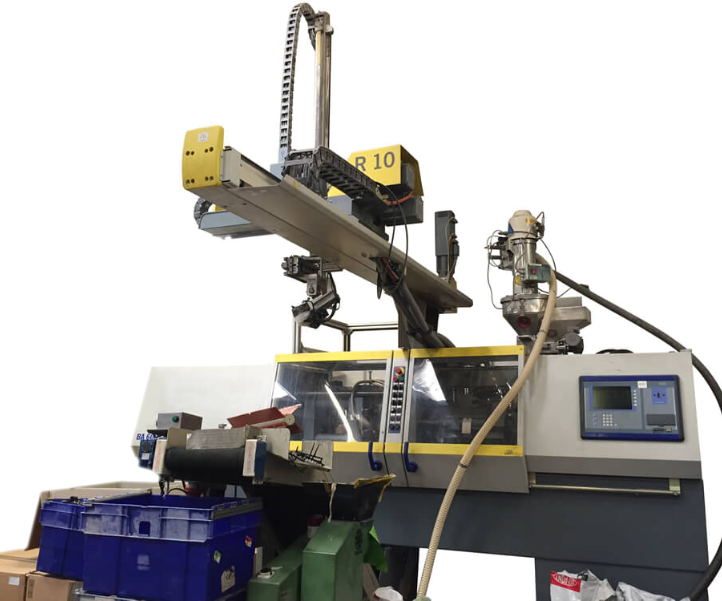

The materials used for plastic injection mouldings comprise thermoplastic and thermosetting plastics for the mixture and steel or aluminium for the moulds. They are subjected to heating and then introduced into moulds to cool and harden to the necessary shape. The heating process is implemented in heated barrels where the plastic materials are mixed. Heating enables the obtention of a uniform mixture which is then forced into metal moulds which are precision machined. The cooled down and hardened mixture takes the shape of the mould into which it is introduced. Moulds are designed by industrial designers and made by toolmakers or mould makers. We carefully observe the process of manufacturing plastic mouldings to produce plastic items, elements, mechanical parts, assemblies, etc.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.