In today’s rapidly evolving manufacturing landscape, customisation is key to staying competitive and meeting the diverse needs of industries ranging from automotive to healthcare. Custom plastic moulding, a cornerstone of modern injection moulding solutions, offers businesses the flexibility to create highly specialised parts and products that meet exacting standards. Partnering with the right plastic moulding company is essential to leverage these benefits effectively. This blog delves into the world of custom plastic moulding, its advantages, applications, and how it can transform your business. We’ll also address common questions and concerns to provide a comprehensive guide on the topic.

Understanding Custom Plastic Moulding

Custom plastic moulding is the process of creating bespoke plastic components tailored to meet specific requirements. Unlike standard moulding, which relies on generic moulds for mass production, custom plastic moulding offers exceptional flexibility in design, material selection, and production methods. A reliable plastic moulding company provides advanced injection moulding solutions to ensure precision and quality throughout this customised manufacturing process.

The Process of Custom Plastic Moulding

Custom plastic moulding involves several key stages:

- Design and Prototyping: The process begins with a detailed design phase, where the exact specifications of the part are determined. This is often followed by prototyping, where a small number of units are produced to test the design before full-scale production begins.

- Material Selection: Choosing the right material is crucial in custom plastic moulding. The material must meet the functional requirements of the product, whether it’s durability, flexibility, resistance to chemicals, or other properties. Common materials include polypropylene, ABS, nylon, and polycarbonate.

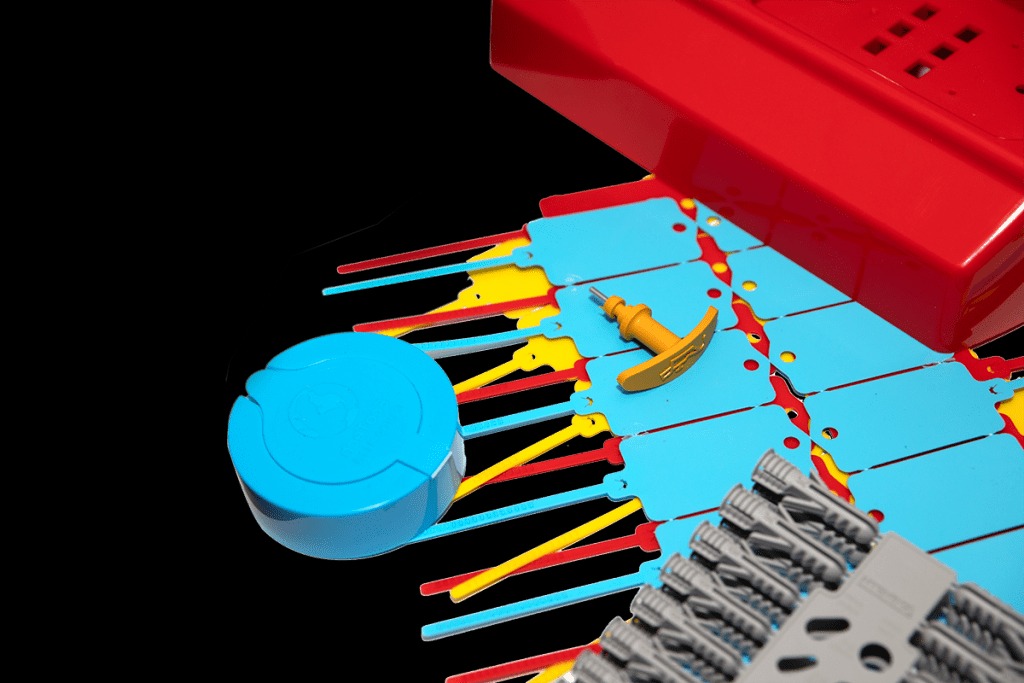

- Tooling and Mould Creation: Once the design and material are finalised, the next step is to create the mould. This is often the most significant investment in the process, as the mould must be precision-engineered to ensure consistent quality in the final products.

- Injection Moulding: The actual moulding process involves injecting molten plastic into the mould, where it cools and solidifies into the desired shape. This step requires careful control of temperature, pressure, and timing to ensure the highest quality.

- Finishing and Quality Control: After moulding the parts, the team trims, paints, or assembles them and performs rigorous quality control checks to ensure each part meets the required specifications.

Benefits of Custom Plastic Moulding

As a trusted plastic moulding company, we play a crucial role in delivering custom plastic moulding and advanced injection moulding solutions. These processes allow businesses to create bespoke plastic components tailored to meet exact specifications, offering unparalleled flexibility in design, material selection, and production methods. By leveraging the expertise of a skilled plastic moulding company, you can achieve precision, efficiency, and innovation in your manufacturing projects:

Precision and Accuracy: Custom moulding allows for the creation of parts with extremely tight tolerances, ensuring that each component fits perfectly within its intended application.

Material Versatility: Choosing from a wide range of materials allows businesses to tailor the final product to specific needs, like resistance to heat, chemicals, or wear and tear.

Cost Efficiency: Although the initial costs of tooling and mould creation can be high, custom plastic moulding often leads to lower per-unit costs in high-volume production. The ability to produce large quantities of parts quickly and with minimal waste also contributes to cost efficiency.

Design Flexibility: Custom plastic moulding enables complex geometries and intricate designs that would be difficult or impossible to achieve with other manufacturing methods. This flexibility is particularly valuable in industries like aerospace and medical devices, where precision and innovation are critical.

Scalability: Custom plastic moulding supports both small and large production runs, enabling businesses to scale production up or down based on demand.

Industry-Specific Applications of Custom Plastic Moulding

A wide range of industries use custom plastic moulding, each with unique requirements and challenges. Here’s how key sectors apply it:

1. Automotive Industry The automotive sector relies heavily on custom plastic moulding for the production of various components, including dashboards, bumpers, and interior trims. These parts must meet strict standards for durability, safety, and aesthetics. Custom moulding allows manufacturers to create parts that not only meet these standards but also contribute to the overall design and functionality of the vehicle.

2. Healthcare and Medical Devices In the healthcare industry, custom plastic moulding is essential for producing medical devices, surgical instruments, and diagnostic equipment. The ability to create sterile, high-precision components that can withstand harsh environments is crucial. Additionally, the flexibility of custom moulding allows for the production of bespoke devices tailored to individual patient needs.

3. Consumer Electronics The consumer electronics industry benefits from custom plastic moulding in the production of housings, connectors, and internal components. As electronic devices become more compact and complex, the demand for precision-engineered plastic parts has grown. Custom moulding provides the solution by enabling the production of parts that meet the exact specifications of modern electronic devices.

4. Aerospace Aerospace applications require components that are lightweight, durable, and able to withstand extreme conditions. Custom plastic moulding meets these requirements, allowing manufacturers to produce parts that are both strong and light, contributing to the overall efficiency and safety of aircraft.

5. Industrial and Manufacturing In industrial applications, injection moulding solutions are used to create parts that are integral to machinery and equipment. These parts often need to be resistant to chemicals, heat, and mechanical stress. Custom moulding creates components to meet the exact specifications required for optimal performance in demanding environments.

Addressing Common Concerns and Questions

When considering injection moulding solutions, potential buyers often have several questions and concerns. Here, we address some of the most common ones:

1. How much does custom plastic moulding cost? The cost of custom plastic moulding varies depending on factors such as the complexity of the design, the type of material used, and the production volume. While the initial costs for tooling and mould creation can be high, the per-unit cost decreases significantly with higher production volumes.

2. How long does it take to produce custom moulded parts? The timeline for producing custom moulded parts depends on the complexity of the design and the production volume. Typically, the design and prototyping phase can take several weeks, followed by mould creation and production. However, advances in technology, such as rapid prototyping, have significantly reduced lead times.

3. What materials can be used in custom plastic moulding? A wide range of materials can be used in custom plastic moulding, including thermoplastics like polypropylene, polyethylene, ABS, and nylon. The choice of material depends on the specific requirements of the part, such as strength, flexibility, and resistance to environmental factors.

4. Can custom plastic moulding be used for small production runs? Yes, custom plastic moulding is suitable for both small and large production runs. While it’s often more cost-effective for larger volumes, the ability to create precise, high-quality parts makes it a viable option for smaller batches as well.

5. How does custom plastic moulding ensure quality and consistency? Quality and consistency are ensured through rigorous design, tooling, and production processes. Advanced machinery, precise control of temperature and pressure, and thorough quality checks all contribute to producing parts that meet the required specifications every time.

The Role of a Plastic Moulding Company

When it comes to plastic moulding, choosing the right partner is crucial. Stephens Plastic Mouldings offers a comprehensive range of injection moulding services that cater to the specific needs of various industries. Their expertise in plastic moulding, combined with state-of-the-art equipment and a commitment to quality, makes them an ideal partner for businesses looking to innovate and grow.

1. Expertise and Experience With years of experience in the industry, Stephens Plastic Mouldings has developed a deep understanding of the intricacies involved in plastic moulding. Their team of skilled engineers and technicians work closely with clients to develop solutions that meet their unique needs.

2. Advanced Technology Stephens Plastic Mouldings is equipped with the latest technology, including high-precision injection moulding machines and advanced prototyping tools. This allows them to produce parts with exceptional accuracy and consistency, regardless of the complexity of the design.

3. Comprehensive Services From initial design and prototyping to full-scale production and assembly, Stephens Plastic Mouldings offers a complete suite of services. Their end-to-end approach handles every aspect of the moulding process with the utmost care and precision.

4. Commitment to Quality Quality is at the core of everything Stephens Plastic Mouldings does. They adhere to strict quality control standards, including ISO 9001 certification, to ensure that every part they produce meets the highest standards of excellence.

5. Customer-Centric Approach At Stephens Plastic Mouldings, customer satisfaction is paramount. They work closely with clients to understand their needs and deliver solutions that exceed expectations. Whether you’re developing a new product or improving an existing one, their team helps you achieve your goals.