Here at Stephens Plastic Mouldings, we have become renowned in our field as plastic injection moulders in the West Midlands. While we are experts in mass-producing plastic injection moulds, we can also adhere to low volume plastic manufacturing (also known as short runs). In some cases, businesses do not require large quantities of plastic moulds. And, therefore, they find it difficult to source manufacturers who undergo small batch plastic manufacturing.

However, we pride ourselves on meeting all batch numbers requests for the production of low volume plastic parts. In this article, find out why businesses need low volume plastic manufacturing and how this could potentially suit your company too.

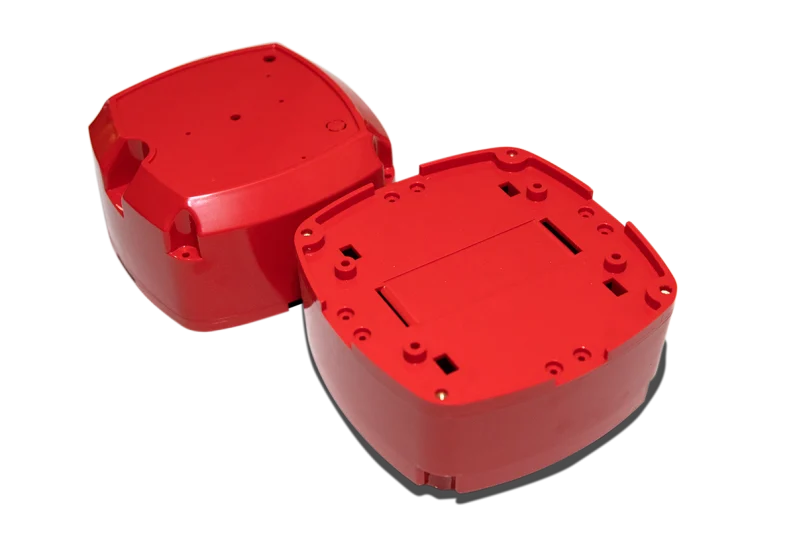

Low Volume Plastic Manufacturing

In most cases, businesses enjoy the flexibility and immediate reliability of having plastic parts on hand at all times. However, this doesn’t always suit smaller companies or those who only need small batch numbers. With that in mind, our specialised low volume plastic moulding manufacturing can provide clients with complete production-quality parts in quantities of as little as 10.

We can comply with low and high-volume injection moulding with a level of service that isn’t often found with manufacturers today.

Who benefits most from small batch plastic manufacturing?

As previously mentioned, small and medium-sized businesses benefit the most from low volume plastic parts. This is because, in most cases, their manufacturing volumes won’t be as extreme as more giant corporations. Whether it’s an automotive business that requires bespoke custom builds or prototypes for the medical sector for new technology, our low volume plastic parts are the answer.

Main Advantages of Manufacturing in Small Amounts

What are the main advantages of manufacturing in a small volume? There are several benefits to our small batch plastic moulding manufacturing.

Firstly, you can cut costs by never committing to a minimum order. By using less expensive tooling, it offers the ability to reduce human resources and materials. Consequently, there is a reduction of costs for both our client and our company.

Secondly, if your business is open to accessing emerging markets, this is an efficient way of trialling a product.

If successful, you can then take advantage of our mass plastic production. Contributing to the above, you are given ease and flexibility for changing and amending designs if necessary. In addition, it offers even shorter production times than we already strive to meet. Furthermore, it allows companies to test areas they are unsure of whether to commit to it or not.

FAQs

What is low-volume plastic manufacturing?

Low-volume plastic manufacturing, also known as short runs, is the production of plastic parts in smaller quantities, often for businesses that do not require large batch sizes. This method allows for the production of high-quality parts without committing to mass production.

Who benefits most from small batch plastic manufacturing?

Small and medium-sized businesses benefit the most from low-volume plastic manufacturing. Industries such as automotive and medical sectors, which require bespoke or prototype parts, find this service particularly advantageous.

What are the advantages of manufacturing in small volumes?

Manufacturing in small volumes offers several benefits, including cost savings by avoiding minimum order commitments and using less expensive tooling. It also allows for flexible and quick production times, making it ideal for trialing new products in emerging markets without significant financial risk.

How does Stephens Plastic Mouldings ensure quality in low-volume production?

At Stephens Plastic Mouldings, we apply the same level of quality control and precision to low-volume plastic injection moulding as we do to large-scale production. Our processes are closely monitored to guarantee that every part meets our high standards for durability and accuracy.

Can low-volume manufacturing help my business grow?

Yes, low-volume manufacturing provides flexibility and efficiency, allowing your business to test new products and markets without a full-scale commitment. This approach can help you identify growth opportunities and respond quickly to market demands.

Use Stephen Plastic for Your Plastic Injection Moulding Manufacturing

No matter the size of the project, we ensure the same level of quality in every single production process. Our low volume plastic injection moulding manufacturing, is closely monitored and regulated to meet our guarantee of precision and durability. With decades of experience in plastic injection moulding, we can execute a complete turn-key solution to all low volume plastic injection moulding production.

For more information on how we can provide you with impeccable low volume plastic injection moulding, get in touch with our team. We can help you open your business up to growth opportunities. Call us today on 0121 544 5808.