Acrylonitrile Butadiene Styrene Injection Moulding

There are many materials to choose from here at Stephens Plastic Mouldings. However, one that comes to mind for injection moulding manufacturing is Acrylonitrile Butadiene Styrene (ABS). It has the advantage that it can easily be recycled. In addition, people use it for a variety of applications. With our years of experience, we can help you determine which is the right material for your plastic injection moulding project.

Acrylonitrile Butadiene Styrene

ABS, Acrylonitrile Butadiene Styrene (C8H8)x· (C4H6)y·(C3H3N)z) is an opaque thermoplastic with a glass transition temperature of 105 °C (221 °F). Therefore, being thermoplastic at this relatively low temperature it becomes a liquid.

Thermoplastics can be heated to the melting point, cooled, and then heated again. All without suffering any significant deterioration. Therefore, it makes ABS ideal for plastic injection moulding manufacturing with the added advantage that it can easily be recycled.

ABS is made using a process called emulsion using continuous mass polymerization. It involves combining a number of ingredients which do not normally mix together to create a single substance. It is a terpolymer created by combining acrylonitrile (15-35%) and styrene (40-60%) in the presence (5-30%) of polybutadiene. ABS is also an amorphous polymer and does not have the ordered characteristics associated with crystalline solids.

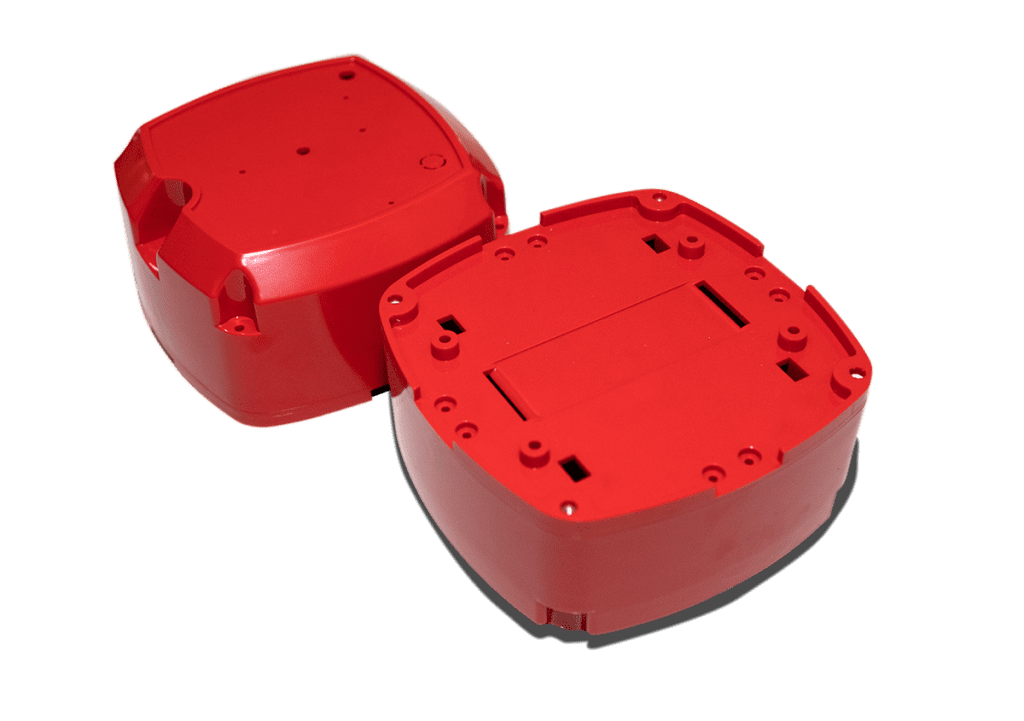

This strong, stiff and inexpensive plastic which stands up well to external impacts. Therefore, it is frequently used for protective packaging. It is also easy to machine and can be painted, coloured, sanded, and glued. Making it ideal for housings for power tools or cameras, which require varying textures.

Other benefits include its light weight and the fact that and it is relatively inexpensive. Furthermore, it has a high level of resistance to corrosive chemicals. In addition, it does not contain any known carcinogens although it is not recommended for medical implants. ABS is commonly used to make computer keyboard keys, pipes, car body parts, protective headwear, musical instruments, heads for golf clubs, and LEGO building bricks.

ABS is a versatile, inexpensive thermoplastic which can be used in a wide variety of applications and has the great advantage that it can be recycled. At Stephens Injection Moulding we frequently use ABS on its own or in combination with other thermoplastics, and our experienced team will be happy to advise you as to whether it is the right choice for your plastic injection moulding project.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.