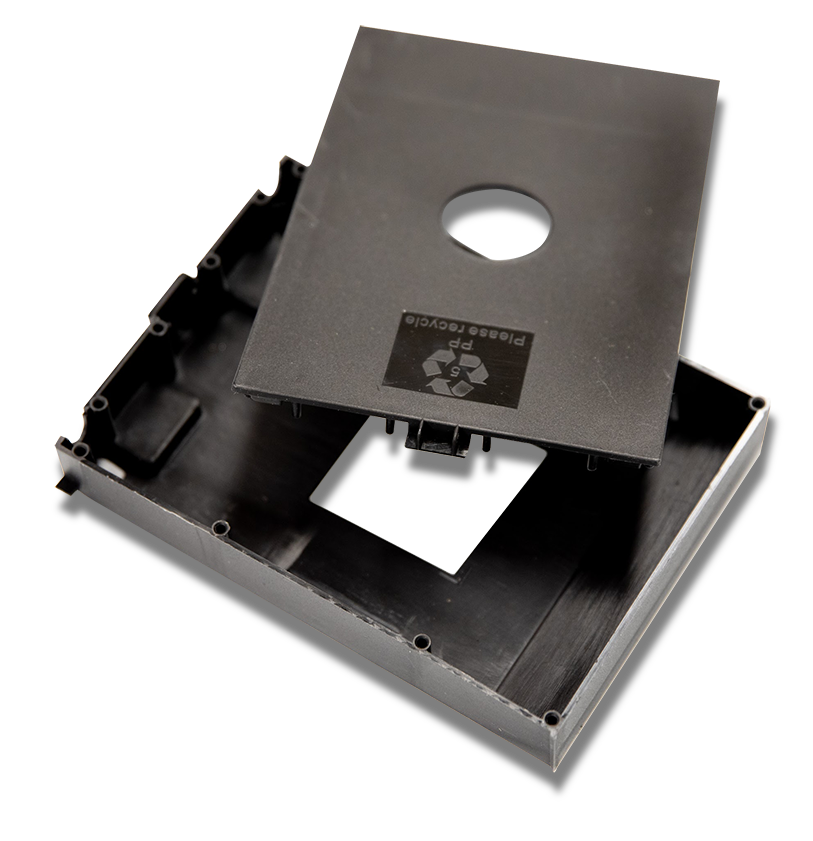

Chi Mei PW-95 Plastic Injection Moulding

Stephens Plastic Mouldings Mouldings Limited has a wide array of injection moulders to supply all your plastic injection moulding needs. We have been in the plastic moulding industry since January 2011 and have supplied thousands of clients all over Birmingham, West Midlands. We have used a variety of plastic materials for injection moulding projects, one of which being: Chi Mei PW-95. Our mission is to deliver to their loyal patrons the best plastic injection moulding with our years of expertise. As well as, using our creative, innovative minds, and genuine passion by leveraging modern machinery and the latest approach.

Chi Mei PW-95 Injection Moulding

Stephens Plastic Mouldings Mouldings Limited has a wide array of injection moulders to supply all your plastic moulding needs. They have been in the plastic moulding industry since January 2011 and have supplied thousands of clients all over Birmingham, West Midlands. Their mission is to deliver to their loyal patrons the best plastic injection moulding with their years of expertise, creative and innovative minds, and genuine passion by leveraging modern machinery and the latest approach.

They cater to a wide variety of materials such as Chi Mei PW-957 injection moulding. This material is used generally as this is UV stabilised or weather resistant. Let us get to know more about this material as we go along.

Flame-Rated Material

This flame-rated material is designed for the plastic injection moulding method. This material complies withRoHS compliant with a flame rating of IEC 60695-11-10 HB. The mass density of Chi Mei pw-957 material is around 1.07 g/cm3 in 23°C test condition. The typical value of the gloss of this material is 97 when using the ASTM D 523 testing method. Its melt flow index is around 23g/10 min and a Vicat Softening Temperature of 105°C.

High Flow Material

This material has an off-white colour and takes the form of a pellet-like shape. It has a high gloss surface and colour stability which enhances the overall appearance of your plastic moulding. This material has high flow and weather-resistant, making it one of the preferred moulding materials in the Asia Pacific, Latin America, North America, Europe, and Africa and the Middle East.

Weather-Resistant Capabilities

Chi Mei pw-957 injection moulding is an ASA or Acrylonitrile Styrene Acrylate product which is a copolymerization of acrylonitrile, styrene, and acrylic rubber. Usually, when combined with ABS, ASA not only maintains the characteristics of ABS but also adds the weather-resistant capabilities of acrylic.

Stephen Plastic Mouldings Materials

This plastic injection moulding material has a tensile strength of 41.1 MPa and a flexural strength of 53.6 MPa. Its yield stress is around 50 MPa while its Flexural modulus at 23°C is about 1900 MPa. Its notched Izod at 1/8 inch is 2.8ft-lbs/in and 1.9 ft-lbs/in in ¼ inch. For its thermal properties, its annealed heat distortion temperature at 120°C/hour ¼ inch is around 95 degrees Celsius.

However, with the unannealed heat distortion temperature at 120°C/hour ¼ inch, the result decreased to around 85 degrees Celsius.

Types Of plastic Materials

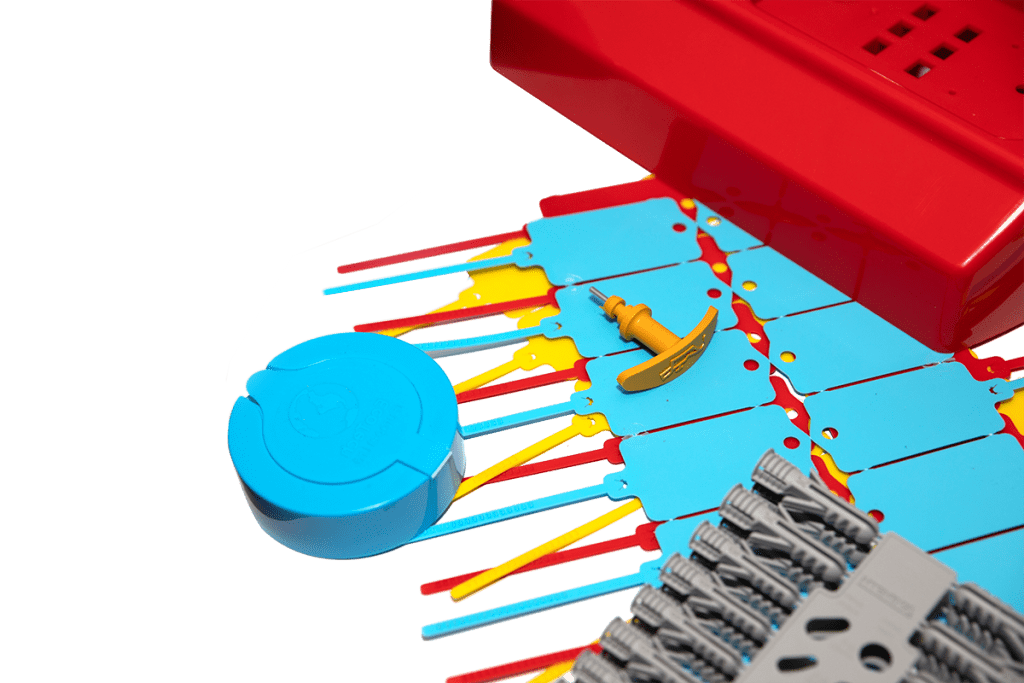

Basically, Stephens Plastic Mouldings Mouldings Limited can work with all types of plastic materials for plastic injection moulding. The company uses state-of-the-art machineries with the most recent approach to ensure its clients the best service and result. We can help you create, design, innovate, prototype, manufacture, and deliver all plastic injection mouldings that you need.

By working with us you can be guaranteed of indisputable thinking with the freshest approach. Our thousands of customers can confirm and verify the company’s highly professional service and top-notch results.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.