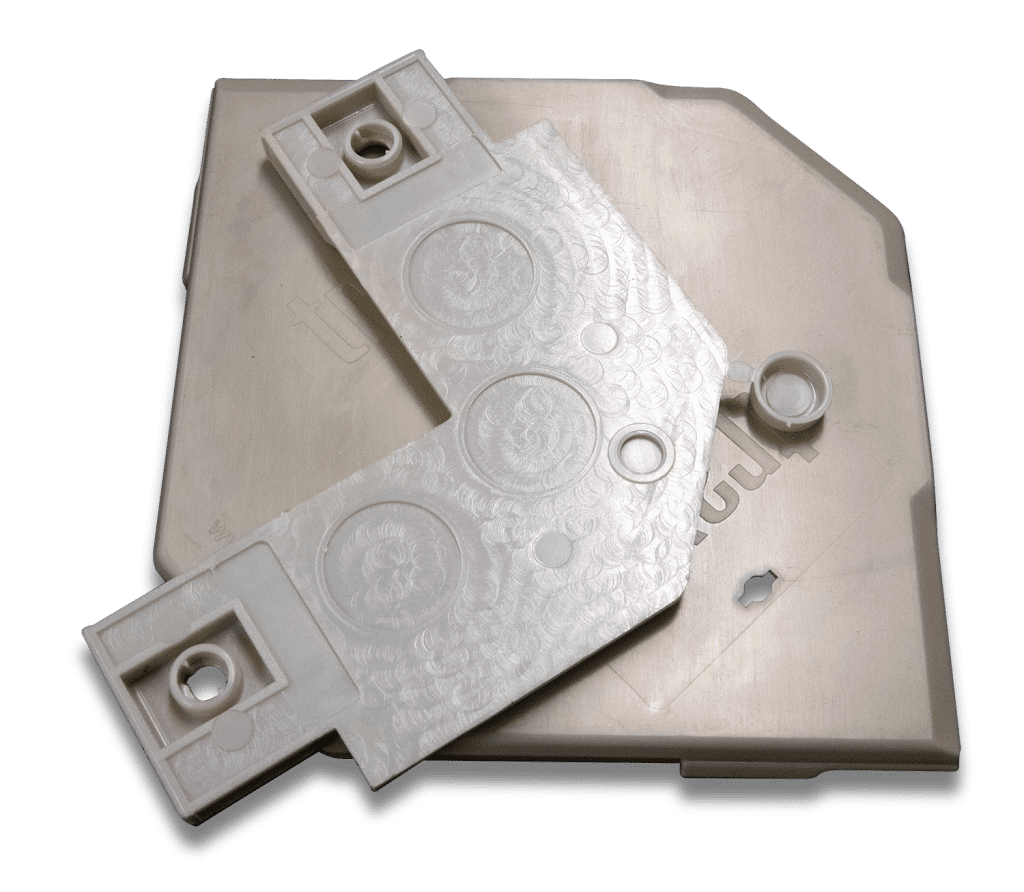

Polyurethane Plastic Injection Moulding

Stephens Plastic Mouldings are proud to offer many materials for our plastic injection moulding services. In addition, our many years or experience enables us to give top quality services at develop an effective technique. If you are unsure of the material you require, get in touch. We will be happy to assist you to decide on the correct material for your application. However, one material in particular we use for plastic injection moulding is Polyurethane.

Polyurethane, also known as PUR or PU, is a versatile material with properties that allow it to be used almost anywhere. In addition, it offers comfort, protection, and design in a number of items we use every day. In other words, our lives would be very different if it weren’t for PUR. Consequently, Polyurethane is a popular material for injection moulding.

What Are The Key Features Of PUR?

PUR has a low weight, a long lifespan, and a high elasticity. Additionally, it is shape-stable, chemically resistant, and oil-resistant. PUR is also weatherproof and can withstand both low and high temperatures (wind and UV radiation). It’s non-static, and it’s excellent at insulating and silencing.

Two component products – PUR is a liquid two-component substance made up of polyol and isocyanate. When these two are combined, a reaction occurs, yielding polyurethane. The properties can be adjusted according to the intended application depending on how the material is mixed. In addition, what manufacturing method is in use.

Examples Of Polyurethane (PUR) Applications

It can be tailored to be either rigid or flexible, and is the material of choice for a broad range of end-user applications such as:

- Insulation of refrigerators and freezers

- Building insulation

- Cushioning for furniture

- Mattresses

- Car parts

- Coatings

- Adhesives

- Tyres

- Composite wood panels

- Shoe soles

- Sportswear

Polyurethanes are adaptable, contemporary, and clean. They are in use in a wide range of applications to produce a wide range of consumer and industrial goods that make our lives easier, more comfortable, and environmentally sustainable.

What Are The Benefits Of Polyurethane?

- Wide Range of Hardness

- High Load Bearing Capacity

- Flexibility

- Abrasion & Impact Resistance

- Tear Resistant

- Resistance to Water, Oil & Grease

- Electrical Properties

- Wide Resiliency Range

- Strong Bonding Properties

- Performance in Harsh Environments

- Mold, Mildew & Fungus Resistance

- Colour Ranges

- Economical Manufacturing Process

- Short Production Lead Times

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.