Plastic Injection Moulding Halesowen

Plastic Injection Moulding Halesowen

Rely on our expertise for plastic injection moulding Halesowen. For plastic items for any purpose, from small items to large plastic assemblies, our company will offer the entire process from the design to the very plastic injection moulding, together with any innovations you may need. Stephens Plastic Mouldings is a one stop solution for individual items and for the complete package of plastic goods manufactured by injection moulding, in any industry sector and in any area of consumer plastics. The professional quality of our plastic goods is due to our efficient structure and a wealth of experience in the area.

Injection Moulders Halesowen – Idea to Finished Product.

Injection Moulding Explained

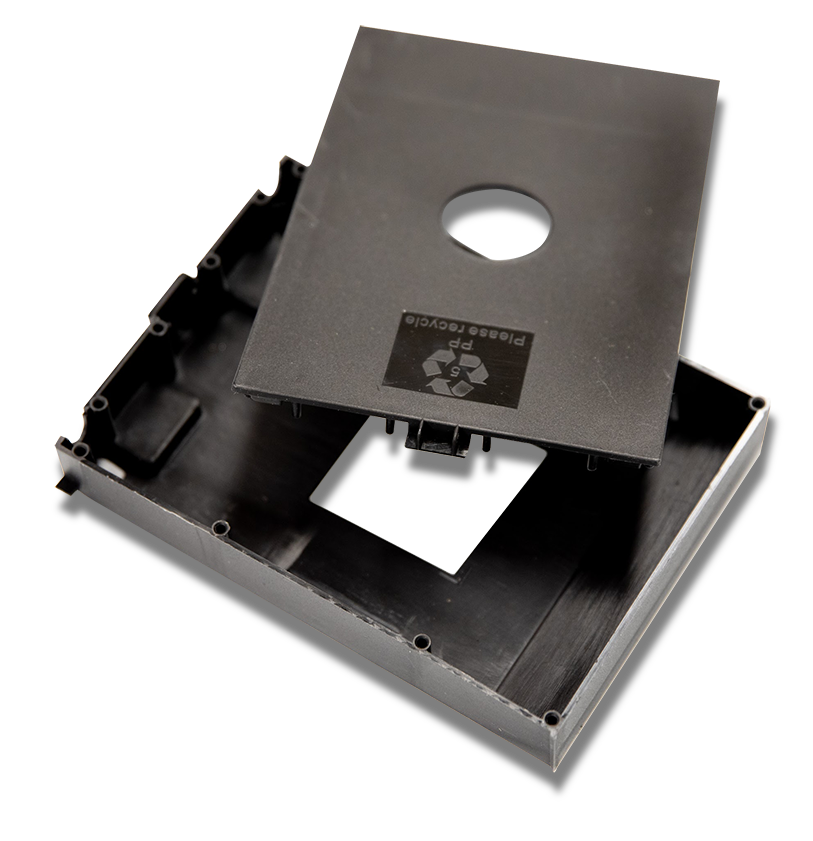

Plastic injection moulding is a widely used manufacturing process where plastic parts, tools, and components are produced from both thermoplastic and thermosetting materials. The process begins by heating the chosen material in a barrel until it reaches a molten state. Once the material is fully melted and mixed, it is injected into a precisely designed moulding cavity under high pressure. As the material cools and hardens within the cavity, it adopts the exact shape and configuration of the mould.

The design of these moulding cavities is a critical step, typically carried out by skilled engineers or industrial designers who work closely with manufacturers to ensure that the final part meets specific functional and aesthetic requirements. Once the design is finalissed, toolmakers or mould makers create the moulds, using materials such as metal, steel, or aluminium, depending on the intended application and production volume. These moulds are then precision machined to exacting tolerances, ensuring that every detail is replicated accurately during the injection moulding process.

The use of high-quality materials for the moulds, along with precise machining, ensures that even complex shapes can be produced with high consistency and durability. This process is ideal for mass production, as the mould can be used repeatedly to produce thousands or even millions of identical parts with minimal variation, making plastic injection moulding a cost-effective and efficient method for creating a wide range of products, from automotive components to consumer goods and medical devices.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.