Lighting

Injection Moulding for Lighting Applications

Stephens Plastic Mouldings is a trusted partner for lighting injection moulding solutions, delivering precision and customisation for a wide range of lighting applications.

With a focus on durability, aesthetics, and functionality, our expertise ensures the production of components that meet the highest standards.

Why Use Injection Moulding for Lighting?

Injection moulding offers numerous advantages for the lighting industry, including:

- Material Versatility: Options for lightweight, durable, and translucent plastics ideal for lighting.

- High Precision: Enables the production of components with complex geometries and detailed features.

- Cost Efficiency: Reduces material waste and supports scalability for both low- and high-volume production.

- Enhanced Strength: Ensures components withstand long-term use and environmental stress.

- Customisation: Allows bespoke designs tailored to meet specific lighting requirements.

Our Capabilities in Lighting Injection Moulding

Stephens Plastic Mouldings provides end-to-end services for lighting injection moulding, including:

Validate designs and test durability before full-scale production.

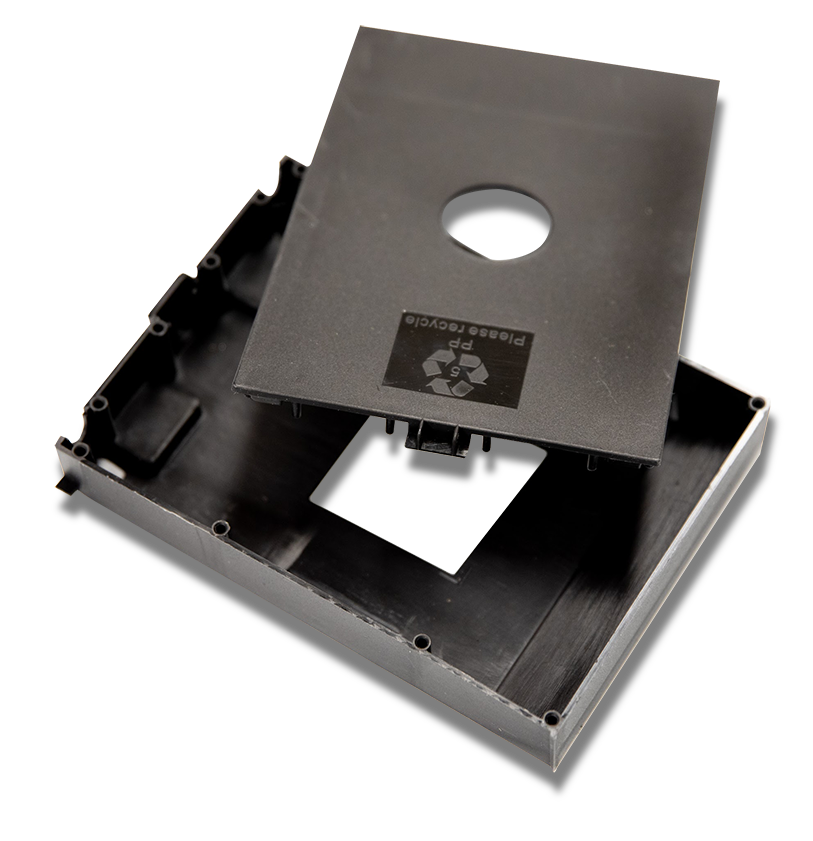

We specialise in creating housings, light covers, and fittings tailored to your unique designs.

From translucent plastics for light covers to flame-resistant materials for safety-critical components, we ensure optimal material selection.

Automation and cutting-edge technology streamline production, reducing costs while maintaining quality.

Applications of Lighting Injection Moulding

Our lighting injection moulding solutions support diverse applications, including:

- Industrial Lighting: Components for heavy-duty and factory lighting systems.

- Commercial Lighting: Tailored solutions for retail, office, and public space lighting.

- Automotive Lighting: Precision parts for headlights, tail lights, and interior vehicle lighting.

- Decorative Light Fixtures: Customised designs for aesthetics and functionality.

Why Choose Stephens Plastic Mouldings for Lighting Injection Moulding?

- ISO 9001 Certification: Guarantees quality and compliance with industry standards.

- Comprehensive Services: From tooling to manufacturing and post-production support, we handle every stage of your project.

- Customer Collaboration: We work closely with you to ensure your vision becomes reality.

- UK-Based Manufacturing: Fast turnaround times and reliable service from a local supplier.

Answering Key Questions

Light covers, housings, fittings, and decorative fixtures.

Translucent plastics, flame-resistant polymers, and weather-resistant materials.

Prototyping in days; full production in 2-6 weeks based on complexity.

Yes, we scale production efficiently for both low and high volumes.

ISO-certified processes, advanced technology, and rigorous quality control measures.

Get Started Today

Partner with Stephens Plastic Mouldings for your lighting project.

Contact us

To learn how our lighting injection moulding solutions can meet your needs.

Call 0121 544 5808 OR Email sales@stephensplasticmouldings.co.uk.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.