Medical

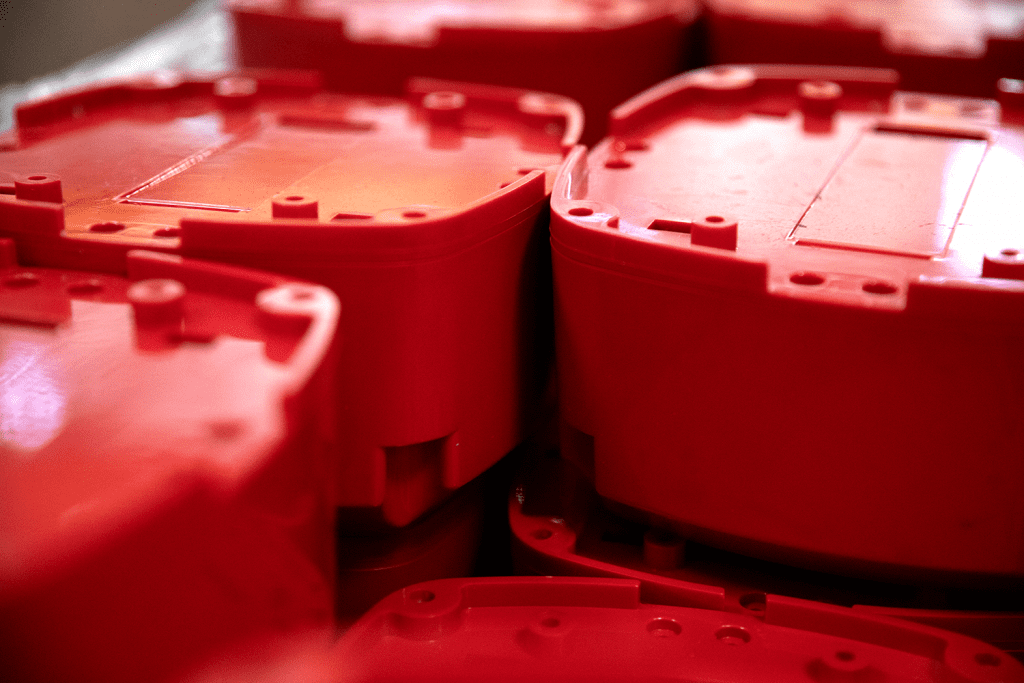

Injection Moulding for Medical Applications

Stephens Plastic Mouldings specialises in medical injection moulding solutions, providing durable, regulatory-compliant, and cost-effective components for healthcare and medical device industries. Our expertise ensures high-quality production with precision and adherence to stringent healthcare standards.

Why Use Injection Moulding for Medical Applications?

Injection moulding delivers unparalleled benefits for the medical industry, including:

- Regulatory Compliance: Medical-grade plastics meet ISO standards for safety and reliability.

- High Precision: Ensures accuracy and tight tolerances essential for medical devices.

- Cost Efficiency: Ideal for high-volume production with minimal material waste.

- Material Versatility: Use of durable, biocompatible, and sterilisable materials for critical applications.

- Customisation: Create bespoke designs tailored to healthcare needs.

Our Capabilities in Medical Injection Moulding

Rapid prototyping for testing and refining medical device designs before full-scale production.

From surgical instruments to diagnostic equipment casings, we deliver components tailored to exact specifications.

Guidance on medical-grade plastics, such as polycarbonate, polypropylene, and PEEK, ensuring safety and functionality.

From design to final assembly, our team provides a comprehensive solution for medical device production.

Applications of Medical Injection Moulding

Our medical injection moulding solutions are applied in:

- Diagnostic Equipment: Casings and internal components for testing devices.

- Surgical Instruments: Durable, sterile tools for precision procedures.

- Implantable Devices: Components designed with biocompatible plastics.

- Pharmaceutical Packaging: Safe, reliable containers and dispensers.

- Personal Protective Equipment (PPE): High-quality face shields, masks, and other protective gear.

Why Choose Stephens Plastic Mouldings for Medical Applications?

- ISO 9001 Certification: Guarantees quality and compliance with healthcare standards.

- UK-Based Manufacturing: Fast and reliable service from a trusted local supplier.

- Decades of Expertise: Experience in producing critical medical components.

- Customer-Centric Approach: Tailored solutions for unique medical industry needs.

FAQs

Surgical tools, diagnostic device casings, implantable components, and packaging.

Biocompatible plastics like PEEK, polycarbonate, and medical-grade polypropylene.

Prototyping in days; full production in 2-6 weeks based on project complexity.

We use certified materials and processes that meet ISO standards for safety and reliability.

Yes, our facilities are equipped for scalable, high-volume manufacturing.

Get Started Today

Partner with Stephens Plastic Mouldings for your next medical project.

Contact us

To learn how our medical injection moulding solutions can meet your needs.

Call 0121 544 5808 OR Email sales@stephensplasticmouldings.co.uk.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.