Design

From Idea to Conception

Stephens Plastic can design and develop your product from initial concept through to pre-production prototype managing the process for optimum results. As experts in injection moulding design serviceswe ensure your project is handled with precision and efficiency. Research invested in the early stages pays dividends in saving time and reducing hassle when it comes to sampling and production. By working with you throughout this crucial stage, Stephens Plastic design team will make sure that all of the required considerations are addressed.

We will work with you step by step to cover:

- Environmental and recycling requirements

- Prototyping options

- Thermoplastic material selection

- Aesthetic and usability factors

- Resilience and suitability

- Health and safety considerations

- Design for manufacture (DFM)

- Development of component

- Mould tooling options

- Production method

By working through a check list of design stage key points like this we can make sure that whatever your injection moulding project we can get it right and make sure that the man hours invested in bringing a plastic product to market are wisely spent.

From a clear manufacturing perspective, our professional designers will analyse the product and question those areas that could benefit from being streamlined. We take into account the complexity and form of mould tool that will achieve a high degree of repeatability when we evaluate your component.

Your injection moulder should be involved at the earliest stage to ensure the component is suitably constructed for the moulding phase, meets the project specification and takes into account key design elements. It is necessary to protect the design and we will recommend that there be a Non-Disclosure Agreement (NDA) in effect.

The level of assistance we provide will depend on a project's status and the level of involvement needed by the client. We can be of support and work with you as a trusted partner, whether you are at the initial concept stage or have a completely developed and defined product.

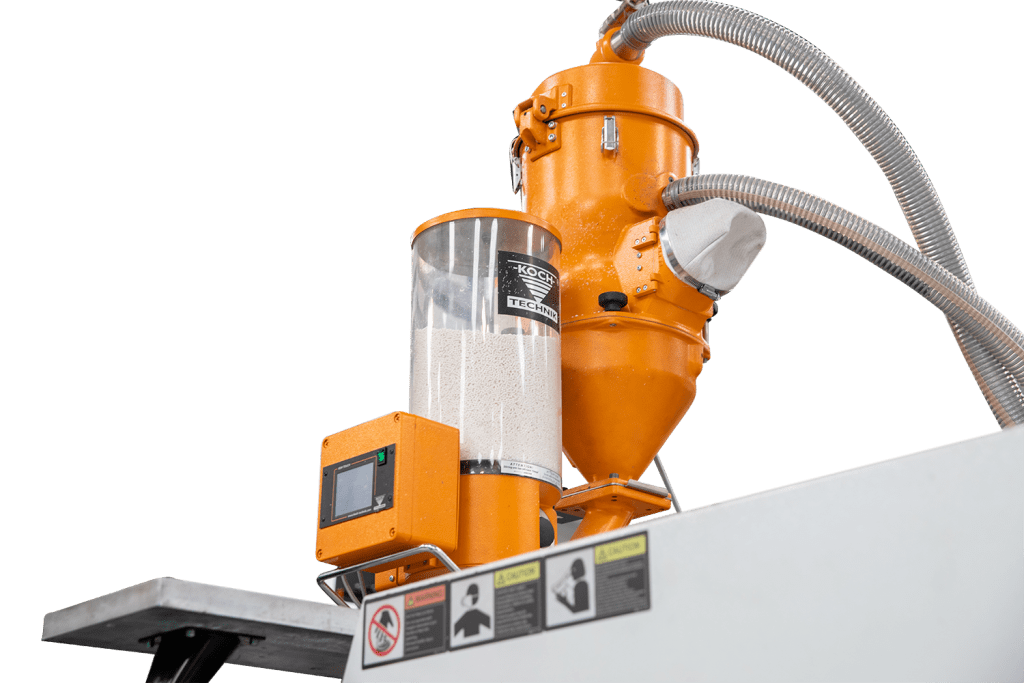

We have a range of cutting edge tools and technology at our disposal in our UK based factory. This enables us to deliver plastic injection moulding and tooling from design to delivery. We work very closely with our customers to make sure we fulfil their requirements exactly.

A key element in a component that is appropriate for its intended application is the choice of moulding material. By partnering with us, we can provide support based on our own years of technical expertise and processing experience.

Considerations include:

Melt Temperature

Thermal Stability

Tensile Strength

Impact Resistance

Chemical Resistance

Conductivity

Shrinkage Rate

Required Additives

Materials typically have distinct properties that influence the strength and function of the final product, and the parameters used in processing these materials are often determined by these properties.

For injection moulding, each material requires a particular set of processes, including melt temperature, fill velocity, strain, shrinkage, and mould temperature.

At any point of a project, we offer a high level of assistance and expertise to deliver a final product you are happy with.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.