Low Volume Injection Moulding Production

Stephens Plastic has the expertise, knowledge, and experience to provide just what you need, whether it’s 10 or 100,000 plastic parts, thanks to its ability to provide both low and high volume injection moulding.

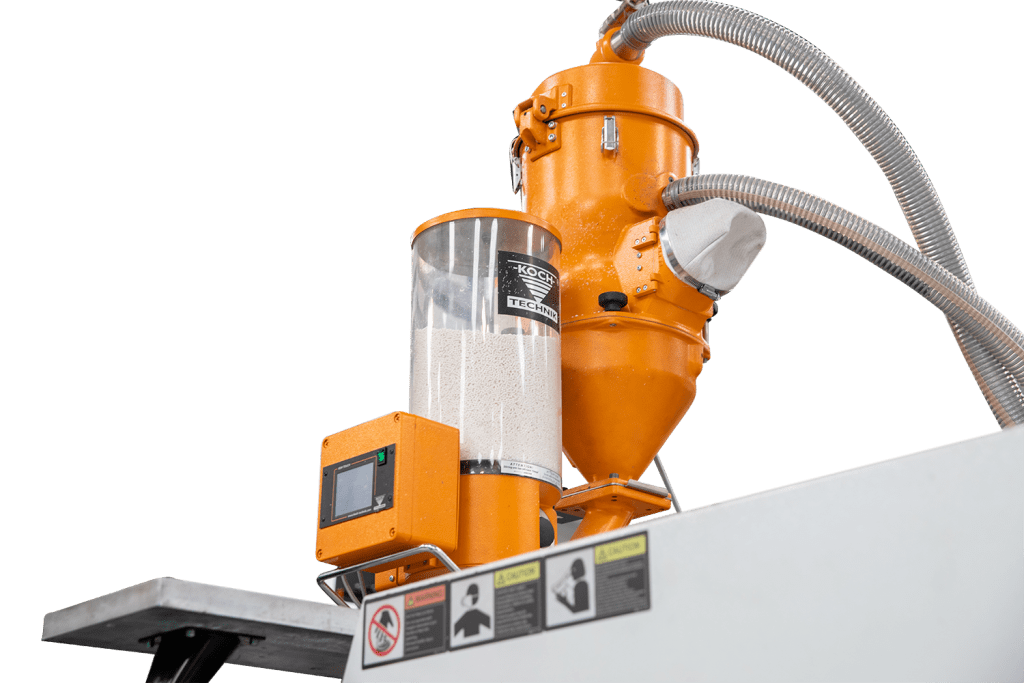

Our Low Volume Injection Moulding is a specialised service that provides complete production-quality parts in quantities of 10,000 or less bits, depending on the method. Our low-volume moulding, also known as short runs, is closely supervised and regulated to ensure that all aspects of mould design and construction are met. Small and medium-sized companies, as well as small-batch manufacturing, benefit from this form of production.

Our expertise in plastic injection moulding helps us to provide a complete turn-key solution for your plastic manufacturing needs, whether it’s an automotive part for bespoke custom builds or prototype construction for healthcare system components.

Advantages of low volume injection moulding production

- Reduce cost with no minimum orders, less expensive tooling

- Provide rapid access to emerging markets

- Allow for faster design changes and more design flexibility

- Shorten production lead times

- Provides a bridge between initial prototypes and high-volume production

Low-volume injection moulding uses softer aluminium moulds and inserts instead of hardened steel ones, which are usually simpler and less expensive to produce. These moulds are obviously not as durable as their hardened steel counterparts, but manufacturers benefit because they don’t always need to be when manufacturing low-volume components. Soft moulds, when used strategically, can lower tooling costs and shorten production times.

At the same time, hardened steel, which is needed for conventional moulds, requires a substantial upfront time and financial investment. Moulds made of aluminium or lower-grade steel, on the other hand, are much less costly to make and can be made far quicker. Manufacturers may use these moulds to test and produce viable parts without having to commit to large minimum orders, allowing them to fine-tune component design and production as required. This enables producers to start manufacturing faster and, in many cases, greatly increase speed-to-market, reducing the time it takes to see a return on investment.

Another important advantage of using softer injection moulds is that they rarely have a negative impact on component quality: when proper design requirements are taken into account, plastic parts made in low quantities are just as good as those produced using hardened steel moulds.

Why choose Stephens Plastic for low volume injection moulding production?

We at Stephens Plastic are always looking for ways to improve our performance. That means working closely with and of our customers during the process, from design and prototyping to post-production and delivery, to ensure that they receive high-quality parts manufactured on a budget and delivered on time.

Contact us today

To learn more about how we can bring your ideas to life.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.