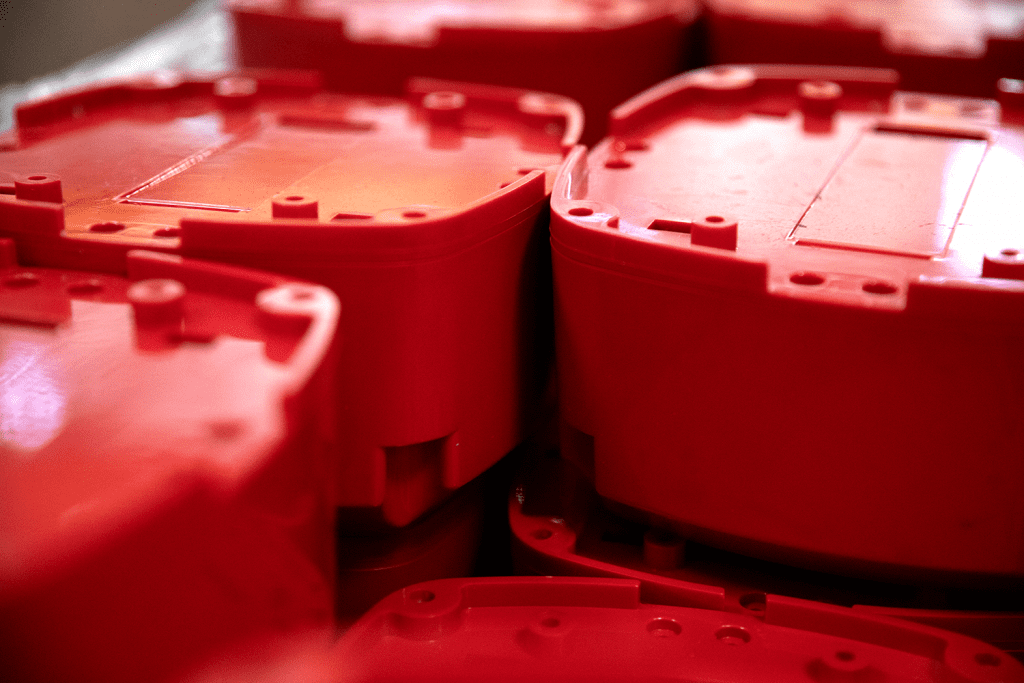

Overmoulding

Our rapid overmoulding processes manufacture custom prototypes and on-demand production parts in days. As a trusted overmoulding company, We use aluminium moulds that provide cost-efficient tooling, manufacturing parts from a variety of thermoplastic materials.

Why choose overmoulding for your project?

At Stephens Plastic Mouldings Injection Moulding we offer this service for your project. Although it requires a more complex design, processing, and material selection than single-shot injection molding, it has several advantages:

- It enables the combination of materials to provide properties that no single resin can provide.

- It can save time and money by eliminating assembly measures.

- It has the ability to meld materials in ways that assembly processes cannot.

- Parts with inserts have more power and longevity.

- We also have a variety of additional secondary resources to help you with your project.

FAQs

Overmoulded thermoplastic products include soft plastics like urethanes and thermoplastic elastomers (TPE) as well as hard plastics like nylon and polycarbonate plus many more.

The substrate parts are produced using a regular injection moulding process involving an aluminum mold with no heating or cooling lines running through it with overmoulding. Our moulders can track fill strain, aesthetic issues, and the basic quality of the parts because cycle times are a little longer.

After the entire run of substrate parts has been moulded, the overmould tooling is assembled and attached to the press. The substrate pieces are manually inserted into a mould, where they are overmoulded with a thermoplastic material.

Plastic overmoulding technology is used in a variety of industries and applications, including Medical Devices, Appliances, Electronics, Consumer, Agricultural, and Automotive goods and components, for a variety of aesthetic and practical purposes.

Plastic overmoulding technology is used in a variety of industries and applications, including Medical Devices, Appliances, Electronics, Consumer, Agricultural, and Automotive goods and components, for a variety of aesthetic and practical purposes.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.