Plastic Injection Moulding

Plastic Injection Moulding Services | UK-Based Manufacturer

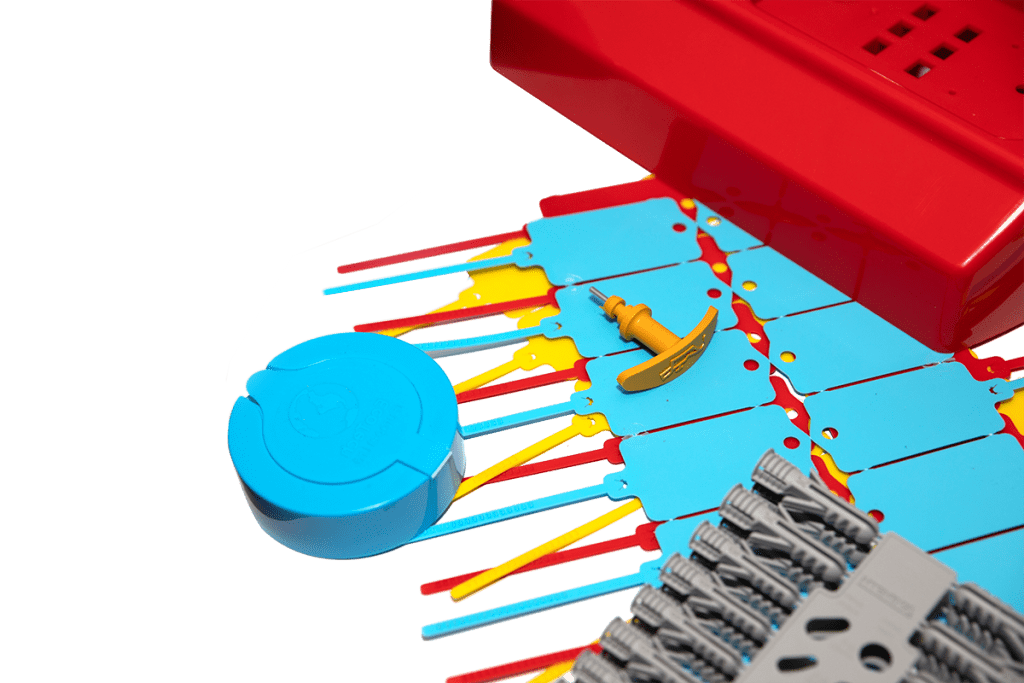

Full-Service Plastic Moulding – Tooling to Production, All Under One Roof

Stephens Plastic Mouldings is a trusted UK-based plastic injection moulding company, delivering end-to-end solutions for clients across the medical, automotive, electronics, construction, and food sectors. From in-house toolmaking to scalable production and post-mould operations, we bring precision, flexibility, and personal service to every project.

If you require case studies and referrals from businesses in the region, please don’t hesitate to contact us. As you can appreciate, in many cases NDAs are in place which limit the public citation of customers; however, we are able to discuss relevant case studies across most regions and industry sectors on a confidential basis.

Whether you’re developing a new component or need consistent delivery for an existing product, we offer the certainty and support that manufacturers depend on.

- Based in the West Midlands.

- ISO 9001:2015 Certified.

- No Minimum Order Quantity.

- National Delivery with Call-Off Scheduling.

Why Choose Stephens Plastic for Injection Moulding?

- In-House Tooling & Production: No third parties, no delays.

- 25-470 Tonne Machine Capacity: For small and large parts.

- Rapid Prototyping: Including free trial tooling for initial runs.

- Advanced Material Knowledge: Including acetal, nylon, ABS, PC, glass-filled compounds.

- Fast Lead Times: Typically 2-6 weeks from tooling approval.

- Responsive Support: Dedicated project managers and direct engineering contact.

Who We Serve

We manufacture plastic components for industries including:

1. Medical & Life Sciences

Diagnostic trays, device housings, and cleanroom-friendly parts using ISO/FDA-compliant polymers.

2. Industrial & OEM Equipment

Durable, custom plastic parts for machinery – brackets, seals, spacers, and covers.

3. Automotive

High-volume clips, sensor housings, and under-bonnet components made to Tier 1/2 standards.

4. Electronics & Smart Infrastructure

PCB enclosures, cable clips, and outdoor sensor housings in flame-retardant, UV-stable plastics.

5. Construction

Pipe brackets, protective caps, and lightweight fixings – built for durability on-site.

6. Food & Beverage Processing

Moulded parts with food-contact certification for automation systems and bottling equipment.

How Our Plastic Injection Moulding Process Works

We review your part design and advise on draft angles, wall thickness, material selection and mouldability.

Your tooling is CNC-machined on-site by our experienced toolmakers - ensuring control, precision, and long service life.

We provide short-run parts or soft tooling (with free trial tools when eligible) to support validation before production.

Using our fleet of machines (25-470 tonnes), we produce consistent parts to your exact specification.

Need more than just a moulded part? We offer ultrasonic welding, inserts, machining, printed part numbers, and assembly.

Parts are packed, labelled and delivered according to your schedule - including call-off orders or JIT fulfilment.

Key Capabilities at a Glance

| Capability | Description |

|---|---|

| Machine Range | 25 to 470 tonne injection moulding machines |

| Part Size Range | From a few grams up to multi-kilo components |

| Material Expertise | ABS, PP, PC, PA66, Acetal, TPEs, glass-filled nylons and more |

| Production Volumes | No minimum order quantity – from prototypes to 500,000+ |

| Tooling In-House | Steel and aluminium tooling CNC-machined on site |

| Process Control | Automated monitoring systems + experienced technicians |

| Certification | ISO 9001:2015 with full batch traceability and QC records |

Client Benefits

- Fast Turnaround: 2-6 week typical lead time.

- Cost Transparency: All-inclusive quotes with tooling, unit cost, and delivery.

- Collaborative Approach: Real people, real contact, from design to delivery.

- Adaptable Supply: Low-volume startup support or full-scale batch production.

- Technical Partnership: We don’t just mould parts; we help improve them.

Related Services

- In-House Toolmaking.

- Plastic Part Prototyping.

- Post-Mould Operations & Assembly.

For more information, take a look at our Plastic Injection Moulding FAQs

We mould with a wide variety of thermoplastics including ABS, PC, acetal, nylon (PA66), TPE, and more. We also offer guidance on suitable materials based on performance, cost, and compliance requirements.

Yes - we offer full tooling services in-house, including new tool creation, tool repairs, and modifications to existing moulds.

Absolutely. We support both early-stage development and low-volume manufacturing without a minimum order quantity.

Yes. We offer sample parts using trial tooling or prototype runs to help validate fit, function and finish.

We deliver throughout the UK and can support international clients on request.

Ready to Start Your Moulding Project?

Stephens Plastic Mouldings is the trusted UK manufacturing partner for companies across Northern Ireland.

Whether you’re replacing an existing plastic part, scaling up a product, or launching something brand new – we’d love to help.

Stephens Plastic Mouldings combines engineering insight, production quality, and personal service to deliver certainty in every batch.

Call 0121 544 5808 OR Email sales@stephensplasticmouldings.co.uk.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.