Tool Trials

Thorough Tool Testing

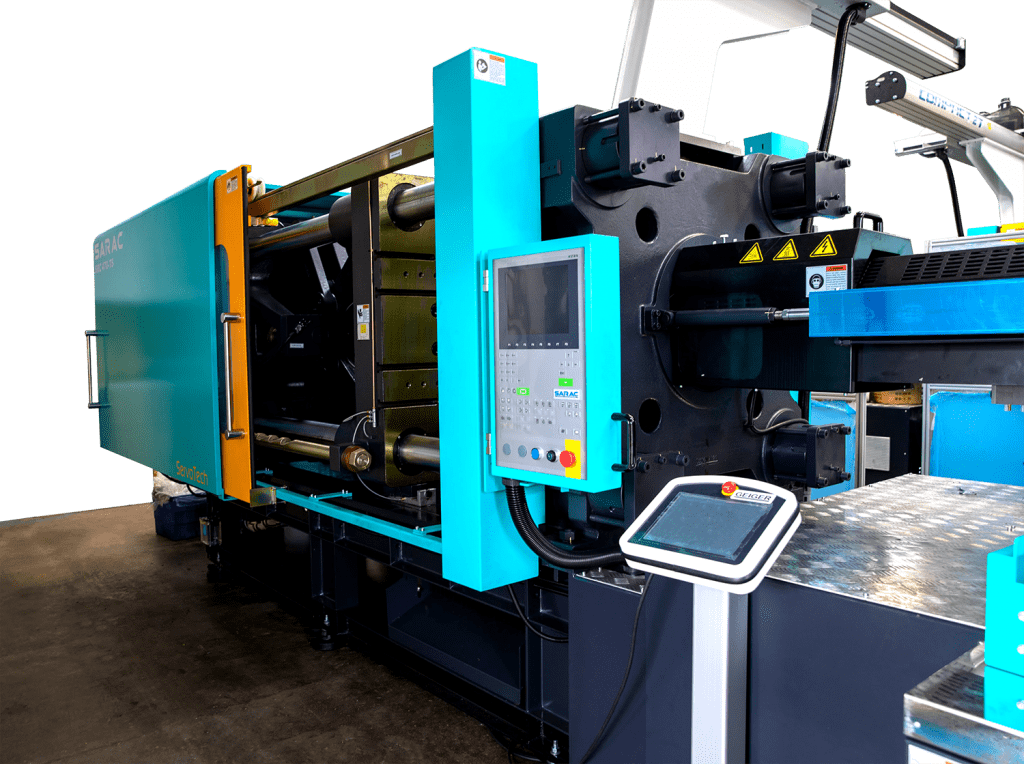

The building blocks for successful injection moulded components is high quality injection mould equipment and tools. From concept through to development, Stephens Plastic offers an unbeatable end-to-end tooling service.

Our depth of technical expertise helps us to provide you with the most appropriate tooling configuration based on the shape of the component, planned batch quantities and the material to be processed. Typically, this is a one-off start-up expense and our objective is to optimise your tooling expenditure through delivering a high-quality mould, tested by our moulding process technicians.

FAQs

Tool trials are integral to the overall success of an injection moulded component. To ensure your experience is smooth sailing, we will perform an assessment of your product to identify any possible problems or cost savings in the configuration of the tool.

Our accredited tooling site offers a comprehensive manufacturing solution to support the mould tooling requirements of our customers, including mould tool trials and design. In our Birmingham plant, the toolroom facility is on site, allowing us complete control over the moulding process from beginning to end. It also enables us to manufacture, service and repair tools.

• Development tooling

• Cold fed simple or complex tooling

• Single tip or multi-cavity hot runner moulds

• Simple open & shut mould tools

• Complex moulds with additional movements

• High cavity, fast cycling tools

Our tool technicians operate from our own, or customer supplied, drawings to produce the mould tooling to a high specification that will meet your project specifications.

The thermoplastic being processed will determine the tool material and surface hardness chosen to best deliver on your production requirements.

For assistance with your products or components, contact Stephens Plastic, whether it's a completely new project or existing parts that you may be experiencing issues with, we offer a comprehensive solution.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.