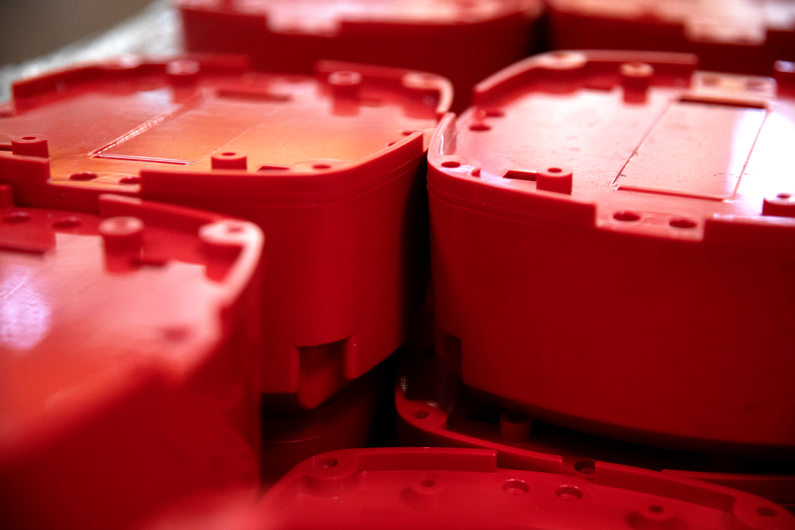

Here at Stephens Plastic Mouldings, we offer comprehensive tooling services so that the final product is of the highest quality. Using modern technology and advanced machinery, combined with our specialist knowledge, we can achieve design, modifications, regular maintenance and refurbishment of parts.

Offering both aluminium and steel, we produce immaculate tool bolsters. These tool bolsters hold a core and cavity that produces our customers’ plastic products, i.e. fasteners. These moulds must withstand the extreme pressures and friction of hot plastic being injected into the core. As specialist tooling suppliers in the UK, we undergo strict measurements to produce matchless plastic injection moulding products.

Why choose steel?

Steel tooling is especially useful for large batches or if the product itself is complex. There are many advantages to the results that our steel tooling services accomplish; this includes efficiency and versatility. No matter how high the production level is, steel tooling is low in cost and this only decreases further with the more product manufactured.

Additionally, steel has a high tolerance to injection heat and clamping pressures. Not to mention, is vastly resistant to chemically corrosive resins such as PVC. Because of this, such metal mould tooling services can create even the most complex shapes in most plastics.

Why choose aluminium?

Tooling suppliers in the UK also heavily rely on aluminium. This easy-to-manipulate material is fantastic when moulds require changes post-setting. It is much easier to machine than steel due to its soft structural properties. Furthermore, aluminium is a better conductor of heat, making it ideal for injection moulding purposes.

Our aluminium tooling services offer low manufacturing costs in both time and money. As this material tends to create simplified designs, this makes for a rapid turnaround, no matter the batch size. This system is also compatible with a wide range of materials, including PC and LCP.

Which suits your needs?

If you’re unsure which material best suits your tooling needs, our specialist team can shed some light. With over 20 years of experience, we have perfected each step of our methods to ensure maximum performance in our products. Using our on-site toolroom, we offer a straightforward, fast and effective tooling service for our customers.

Whether your product is of a challenging nature or you require modifications or maintenance on your tool, we have the expertise and resources to meet your requirements.

FAQs

What are tooling services in plastic injection moulding? Tooling services involve creating and maintaining the moulds used in plastic injection moulding. These services include design, modifications, regular maintenance, and refurbishment to ensure the highest quality final product.

What materials are commonly used for tooling in plastic injection moulding? The most common materials used for tooling in plastic injection moulding are aluminium and steel. Each material offers unique advantages depending on the production requirements.

What are the benefits of using steel for tooling? Steel tooling is ideal for large batches and complex products due to its efficiency, versatility, and high tolerance to injection heat and clamping pressures. It is also resistant to chemically corrosive resins like PVC, making it suitable for creating complex shapes.

Why might a business choose aluminium for tooling? Aluminium is easier to machine and modify due to its soft structural properties. It conducts heat better, making it suitable for injection moulding. Aluminium tooling offers low manufacturing costs and rapid turnaround times, ideal for simplified designs and various materials.

How does Stephens Plastic Mouldings handle challenging or complex tooling projects? We have the expertise and resources to manage challenging tooling projects, offering solutions for complex shapes and modifications. Our comprehensive tooling services ensure maximum performance and durability of the final products.

Get in Touch with Us Today

If you’d like further information on our steel and aluminium tooling services, get in touch with our happy and helpful team today at sales@stephensplasticmouldings.co.uk. We are pioneers in plastic injection moulding, and every step that we take in our process is to exceed the expectations of our customers.

While there are other tooling suppliers in the UK, we are one of the only ones to demonstrate such attention to detail. We do this within our premises too; using state-of-the-art machinery and a team of experts, we have the ingredients to meet your exact specifications and timelines.

If you found this blog useful, check out a previous one: ABS Plastic Injection Moulding for the Automotive Industry