Benefits of Injection Moulding

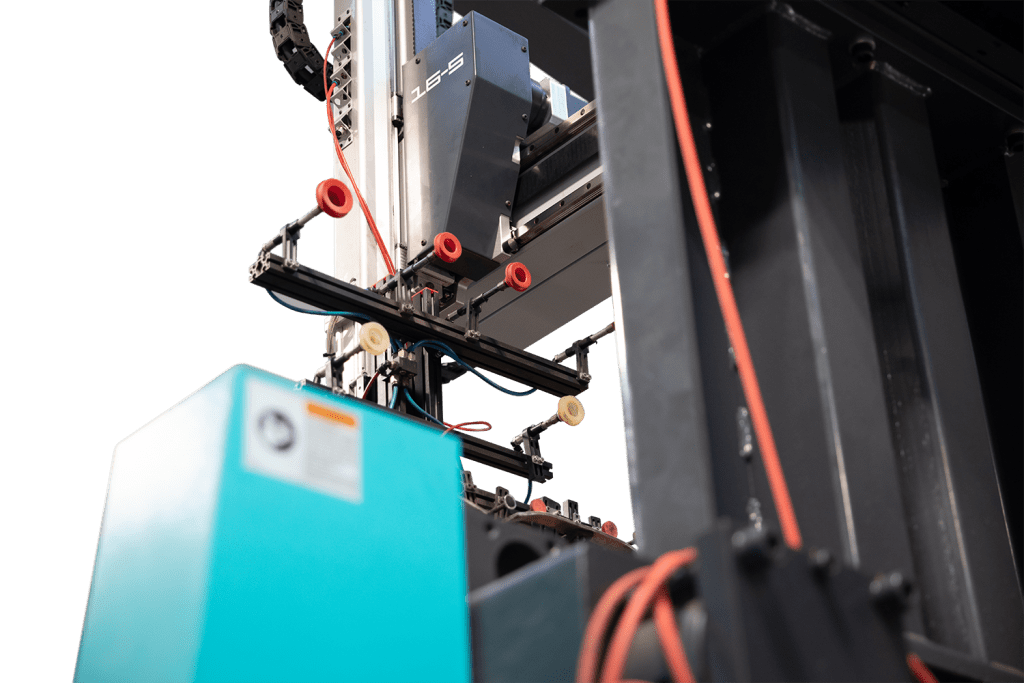

- Fast high quality production and highly efficient

- Automated for efficiency

- Design flexibility

- High-output production

- Large material choice

- Minimal waste and recyclable

- Excellent colour choice and control

- Consistently high quality

- Increased Strength

We have clients from all areas of the UK, including London, Walsall, Wolverhampton, Staffordshire, Coventry, Sandwell.

Materials

- Acrylic

- Acetal

- Glass Filled Nylon

- LEXAN Polycarbonate

- Polypropylene

- Pocan Injection Moulding

- Makrolon

- Nylon 6

- Polycarbonate

- Polyurethane

- TPU / TPE

- Glass Filled PP Injection Moulding